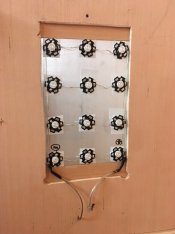

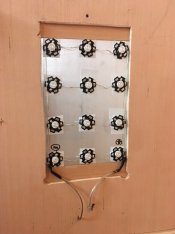

So, I've built a 4x5 exposure unit using 12 UV LEDs, 3W each, 395nm like so

which works fine and I get exposure times of a few minutes (~3) for ziatypes with very even illumination. So far so good.

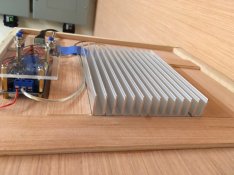

I am using a fairly massive heat sink

but still the heat sink goes to about 58C after 5 minutes or so and you don't want to run the LED's much above 65C.

I am wondering how to do this for a large unit, say 11x14?

The sheer weight of the aluminum in the heat sink becomes a real concern (as well as the cost). I've seen reports of LEDs which were just glued to a sheet of thin aluminum and the light output dropped to less than 1/2 after a year of printing, which to me sounds like to much heat at the junction.

So how to manage heat if you have of the order of 200W of LED's?

which works fine and I get exposure times of a few minutes (~3) for ziatypes with very even illumination. So far so good.

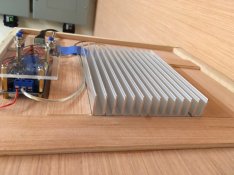

I am using a fairly massive heat sink

but still the heat sink goes to about 58C after 5 minutes or so and you don't want to run the LED's much above 65C.

I am wondering how to do this for a large unit, say 11x14?

The sheer weight of the aluminum in the heat sink becomes a real concern (as well as the cost). I've seen reports of LEDs which were just glued to a sheet of thin aluminum and the light output dropped to less than 1/2 after a year of printing, which to me sounds like to much heat at the junction.

So how to manage heat if you have of the order of 200W of LED's?

.

.