Thiago Lara

Member

Hi, Apugers!

Bought this CPE-2 on fleaBay some months ago to backup my CPA-2. It came with the motor somehow slow... you can see in the video below:

http://www.youtube.com/watch?v=kJvExXiq3jY

I'm in Brazil, and it came from US. So just the shipping to receive it was almost the same value of the processor, sending it back would only make me loose more money, so was not an option. Didn't bother to contact the seller, since the guy basically sent me his trash, it's hard to believe that he didn't knew the processor was defective. After months trying to find someone to service it here, I decided to try it myself. Found a blinking toasted resistor in the control board, it blinks when the motor inverts:

[video=youtube;QKFbIQ0Zp8M]http://www.youtube.com/watch?v=QKFbIQ0Zp8M[/video]

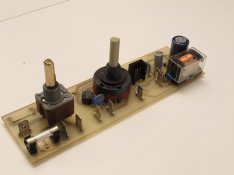

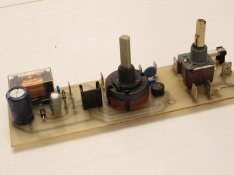

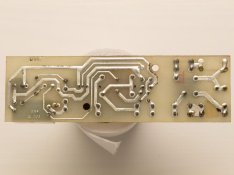

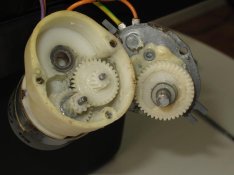

Here's a picture of the board of my processor:

The problem is that I can't identify the resistor by the stripes, I think the former owner has insisted in using it this way during some time, the thing is really toasted, it's gray:

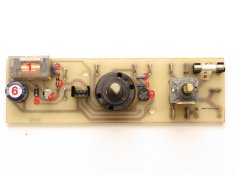

I find the picture below on the internet, this guy has changed the whole board in order to keep the high voltage on the lower speed setting and keep the torque high... another thing, but there's a picture of the original board there... unfortunately it's black and white.

here:http://www.tech-diy.com/Photography/JOBO CPE2 Motor Speed Controller/jobo.htm

Would some lovable owner of a CPE-2 here make me the huge favor of opening the panel of the processor to identify the resistor, so I can try to find one to replace it? This things are identified by the number of the stripes and it's colors, I'm informing myself about it as I research a solution for this machine, I know nothing on electronics, so a picture would be great. But I understand that people here doesn't have digital cameras I've actually thinking on selling all my digital crap everyday since I started with film so if a picture it's not possible just a identification on the colors of the stripes on it will be fine as well.

And since I'm already asking, I would love to know more about resistors and this specific problem. What could have caused it? I read thats usually caused by an overload, but what can be the cause for this overload? A subtle variation in the power? Plugin a 110v machine in a 220v wall socket? I'm wondering if it's something external or another component in the machine which may be the real cause for this toasted resistor. What do you think?

Thank you very much,

Thiago Lara.

Bought this CPE-2 on fleaBay some months ago to backup my CPA-2. It came with the motor somehow slow... you can see in the video below:

http://www.youtube.com/watch?v=kJvExXiq3jY

I'm in Brazil, and it came from US. So just the shipping to receive it was almost the same value of the processor, sending it back would only make me loose more money, so was not an option. Didn't bother to contact the seller, since the guy basically sent me his trash, it's hard to believe that he didn't knew the processor was defective. After months trying to find someone to service it here, I decided to try it myself. Found a blinking toasted resistor in the control board, it blinks when the motor inverts:

[video=youtube;QKFbIQ0Zp8M]http://www.youtube.com/watch?v=QKFbIQ0Zp8M[/video]

Here's a picture of the board of my processor:

The problem is that I can't identify the resistor by the stripes, I think the former owner has insisted in using it this way during some time, the thing is really toasted, it's gray:

I find the picture below on the internet, this guy has changed the whole board in order to keep the high voltage on the lower speed setting and keep the torque high... another thing, but there's a picture of the original board there... unfortunately it's black and white.

here:http://www.tech-diy.com/Photography/JOBO CPE2 Motor Speed Controller/jobo.htm

Would some lovable owner of a CPE-2 here make me the huge favor of opening the panel of the processor to identify the resistor, so I can try to find one to replace it? This things are identified by the number of the stripes and it's colors, I'm informing myself about it as I research a solution for this machine, I know nothing on electronics, so a picture would be great. But I understand that people here doesn't have digital cameras I've actually thinking on selling all my digital crap everyday since I started with film so if a picture it's not possible just a identification on the colors of the stripes on it will be fine as well.

And since I'm already asking, I would love to know more about resistors and this specific problem. What could have caused it? I read thats usually caused by an overload, but what can be the cause for this overload? A subtle variation in the power? Plugin a 110v machine in a 220v wall socket? I'm wondering if it's something external or another component in the machine which may be the real cause for this toasted resistor. What do you think?

Thank you very much,

Thiago Lara.