lbloom

Member

- Joined

- Mar 28, 2011

- Messages

- 29

- Format

- Multi Format

Hello all,

I recently purchased a used Lloyds bulk loader from here. When the door of the loader is closed, I find that the crank does not insert all the way to the cassette, so I can't wind on the film.

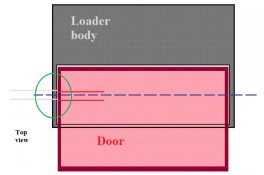

(The daylight design of the Lloyds involves inserting a crank through a hole in the body, past another aligned hole in the closed door, to wind the cassette in the chamber. This design prevents the door from being opened when the film is being wound. Picture #1 shows the door open, and the crank is in the background, very out of focus.)

In my case, the crank passes correctly through the hole on the loader body, but the hole in the door does not seem to align correctly, no matter how tightly I close the door. There is a always a thin section of the door that blocks the path of the crank (crescent seen in Picture #2, within the bore). This is mechanically blocking the crank.

I have tried taking apart the loader and re-assembling it. It seems to be a simple device, and there are no obvious loose or damaged points that I can see. If I apply a great deal of compressive force on the door briefly, I can insert and retrieve the crank with some difficulty, but I believe that this is due to deformation of the bakelite/plastic.

Any idea on what's going on here, and what I can do about it? I'm happy to take more pictures or describe this better, if it helps.

Thanks!

I recently purchased a used Lloyds bulk loader from here. When the door of the loader is closed, I find that the crank does not insert all the way to the cassette, so I can't wind on the film.

(The daylight design of the Lloyds involves inserting a crank through a hole in the body, past another aligned hole in the closed door, to wind the cassette in the chamber. This design prevents the door from being opened when the film is being wound. Picture #1 shows the door open, and the crank is in the background, very out of focus.)

In my case, the crank passes correctly through the hole on the loader body, but the hole in the door does not seem to align correctly, no matter how tightly I close the door. There is a always a thin section of the door that blocks the path of the crank (crescent seen in Picture #2, within the bore). This is mechanically blocking the crank.

I have tried taking apart the loader and re-assembling it. It seems to be a simple device, and there are no obvious loose or damaged points that I can see. If I apply a great deal of compressive force on the door briefly, I can insert and retrieve the crank with some difficulty, but I believe that this is due to deformation of the bakelite/plastic.

Any idea on what's going on here, and what I can do about it? I'm happy to take more pictures or describe this better, if it helps.

Thanks!

Attachments

Last edited by a moderator: