Thank you, yes the plate pivots and the various gear trains move smoothly. The shutter blades open smoothly without jarring or catching.Does the plate pivot on the shaft?

The spring on the main cocking arm is far lighter than I had expected based upon the descriptions on the Ilex Acme 2 shutter.

I've used cotton buds dipped in Isopropyl Alcohol and rubbed around the various sections, which has cleaned some gunk/dirt off..

If I cannot get the delay pallet off I might pour a small amount of Isopropyl Alcohol into the casing and swill it around..

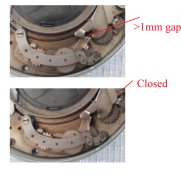

The cable release 'tube' had sprung slightly but I closed that and the cable release no longer slides past the arm.

regards and thanks

Tony