Hi all,

I am putting together plans for turning a small bedroom in our house (roughly 10ft. x 10ft.) into a quasi dedicated darkroom. By that I mean that it will be a permanent darkroom on a daily basis and have no other function, but in the event that i sell this house, it will be relatively easy for me to to convert it back to a functioning bedroom. The plans go like this: both hot and cold water lines will be installed (exposed) coming up through the floor and secured to the wall, the drain will run from the sink through the floor and tied into the drain line in the crawl space (this room is adjacent to the the bathroom). The sink that I feel will do the job is a Delta Sink&Wash Well II model ($249.00); it is of ABS Plastic construction and can be viewed at B&H, I will also be getting the stand and shelf for the sink. I like the idea of the wash well, when I get a dedicated darkroom I intend to graduate to fiber based papers since I will no longer have time restraints due to operating in the kitchen. It seems that that the whole unit can be easily removed if needed. The plumbing can be easily removed and any holes plugged. Plans are to install an exhaust fan in the ceiling with ductwork to carry the exhaust fumes through the attic and on through to a roof vent.

Now, things I am uncertain about and require some advice; I go bonkers trying to input all the differences between the various types and models of such things:

-what is an adequate water temperature control device that may be a minimum, but will get the job done effectively?

-the same type of question for a filtration setup that will get the job done and not cost an arm and a leg

-I have been reading about vacuum breakers, is this necessary and at what position in the plumbing sequence is attached? I have looked at Delta Eco vacuum breaker with fittings also on B&H ($33.00)

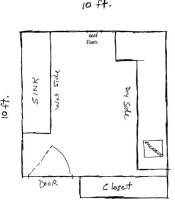

The dark room will layout easily with a "wet side" and a "dry side" and I have included a rouch sketch of the floor plan. The dryside counter top will be modular to facilitate easy removal. I would appreciate any comments if you think I have forgotten something in any of the plans that I have mentioned above.

Many thanks,

Chuck

I am putting together plans for turning a small bedroom in our house (roughly 10ft. x 10ft.) into a quasi dedicated darkroom. By that I mean that it will be a permanent darkroom on a daily basis and have no other function, but in the event that i sell this house, it will be relatively easy for me to to convert it back to a functioning bedroom. The plans go like this: both hot and cold water lines will be installed (exposed) coming up through the floor and secured to the wall, the drain will run from the sink through the floor and tied into the drain line in the crawl space (this room is adjacent to the the bathroom). The sink that I feel will do the job is a Delta Sink&Wash Well II model ($249.00); it is of ABS Plastic construction and can be viewed at B&H, I will also be getting the stand and shelf for the sink. I like the idea of the wash well, when I get a dedicated darkroom I intend to graduate to fiber based papers since I will no longer have time restraints due to operating in the kitchen. It seems that that the whole unit can be easily removed if needed. The plumbing can be easily removed and any holes plugged. Plans are to install an exhaust fan in the ceiling with ductwork to carry the exhaust fumes through the attic and on through to a roof vent.

Now, things I am uncertain about and require some advice; I go bonkers trying to input all the differences between the various types and models of such things:

-what is an adequate water temperature control device that may be a minimum, but will get the job done effectively?

-the same type of question for a filtration setup that will get the job done and not cost an arm and a leg

-I have been reading about vacuum breakers, is this necessary and at what position in the plumbing sequence is attached? I have looked at Delta Eco vacuum breaker with fittings also on B&H ($33.00)

The dark room will layout easily with a "wet side" and a "dry side" and I have included a rouch sketch of the floor plan. The dryside counter top will be modular to facilitate easy removal. I would appreciate any comments if you think I have forgotten something in any of the plans that I have mentioned above.

Many thanks,

Chuck

...

...