1.

English language correction....

2.

Denise, before you take this film as not completely historically accurate

1.

I am stuck.

There are several referances to something that perhaps I was unaware of... can someone bring me up to speed?

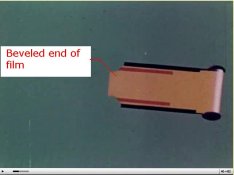

It seems that the narrator says that film (or the backing paper) is in someway "beveled"... at first I thought they were talking about the flange on the ends of the spool, but now I am not so sure.

0.32 0.42 "The yellow backing paper protects the film and the sides REBATES? have been beveled BEVELLED, thereby pushing PRESSING [the film] against the film reel SPOOL FLANGES and THUS avoiding accidental exposure LIGHT LEAKEAGE."

14.40 14.47 "A second inspector checks the sides REBATES? of the film...."

15.03 15.10 "The paper backing is cut in strips and THE SIDES /REBATES beveled BEVELLED, so as to have the film being pushed SO THAT THEY PRESS TIGHTLY against the reels and flanges REEL FLANGES [to avoid exposure]."

Is there something to this?

Do we need a new translation?

2.

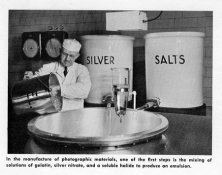

True. However, one shiner is where the narrator seems to imply that the red colored liquid is KBr.

PE has speculated it might be a solution of a rhodium compound, and while this might be plausable, I wonder

a. if that quantity looks right for that amount of emulsion (What 1000 L?)

b. I think that stuff is very expensive... too much to be mixing in that volume for one weeks work...

c. there are 3 colored solutions visable.

red, green, and yellowish brown.

Could the first two not possibly be dyes?

If the dye were one used in relatively high concentrations, the amount shown (dry... being weighed) might make sense.

I just can't see that much rhodium being used for a weeks production.

On the other hand... it could all be mock... for show and jell only.