Hi guys,

A few of you may remember my thread a couple of weeks ago about homebrewing a film processor... well, I've sidelined onto another project. A printer. Specifically, one that uses a laser to print onto photo paper, which is then developed in the normal way.

I know, I'm mad.

Anyway, I obviously need a source of photo paper. I'm leaning towards Ilford Multigrade IV because it's dead easy for me to get through work, and is fairly inexpensive. I've also been looking at Ilfospeed, but I'd have to order that (probably through Silverprint).

What I would like to know is -- what the peak sensitivity of the paper is (i.e. how much light of a certain wavelength is required to fog it to black), what that wavelength is, and how sensitive it is (relatively) at 405nm (the output wavelength of my laser).

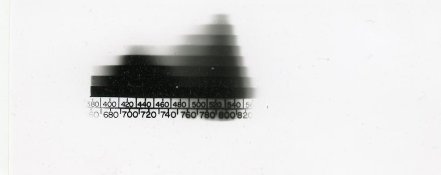

For Ilfospeed this is fairly easy -- the wedge spectrogram would seem to imply that while the response peak is closer to green, the response at 405nm is close to the mean.

For MGIV, the only data presented is an Equal Energy chart with three curves plotted: 0.5, 1.0 and 1.5. X axis is wavelength, and Y appears to be relative response. What does this represent, and how does it compare to a wedge spectrogram?

Why the three different curves -- AIUI the spec sheet states that the data is given based on unfiltered light (i.e. no grading filters) so surely the response would be the same for all three tests?

I know I'm missing something here, but I'm not sure what... :confused:

Thanks,

Phil.

A few of you may remember my thread a couple of weeks ago about homebrewing a film processor... well, I've sidelined onto another project. A printer. Specifically, one that uses a laser to print onto photo paper, which is then developed in the normal way.

I know, I'm mad.

Anyway, I obviously need a source of photo paper. I'm leaning towards Ilford Multigrade IV because it's dead easy for me to get through work, and is fairly inexpensive. I've also been looking at Ilfospeed, but I'd have to order that (probably through Silverprint).

What I would like to know is -- what the peak sensitivity of the paper is (i.e. how much light of a certain wavelength is required to fog it to black), what that wavelength is, and how sensitive it is (relatively) at 405nm (the output wavelength of my laser).

For Ilfospeed this is fairly easy -- the wedge spectrogram would seem to imply that while the response peak is closer to green, the response at 405nm is close to the mean.

For MGIV, the only data presented is an Equal Energy chart with three curves plotted: 0.5, 1.0 and 1.5. X axis is wavelength, and Y appears to be relative response. What does this represent, and how does it compare to a wedge spectrogram?

Why the three different curves -- AIUI the spec sheet states that the data is given based on unfiltered light (i.e. no grading filters) so surely the response would be the same for all three tests?

I know I'm missing something here, but I'm not sure what... :confused:

Thanks,

Phil.

.

.