I recently bought a used Epson Perfection 3200 scanner for the princely sum of $11 from our local Goodwill. It came with the 35mm slide holder but nothing else. It is working fine with VueScan via USB no issues there. This my first flatbed film scanner. I bought the flatbed to do 120 &127, 617, & 70mm scans - B&W, colour neg & colour slides.

I scanned a couple of 35mm slides with the Epson 3200 but they were not very sharp. I suspected that I had a focus issue. I have an old 35mm Minolta Dimage Scan Speed SCSI scanner that is a lot sharper.

I did a flatbed scan of my stainless steel guitar string gauge (yeh I also work on guitars ) as it is flat and won't flop around like film does. The scan is extremely sharp:

) as it is flat and won't flop around like film does. The scan is extremely sharp:

I scanned it at 3200 DPI to a TFF file & converted it to jpg & reduced for posting here. No complaints with the flatbed mode scan.

I then did a scan in transparency mode B&W with the string action ruler lying on the scanner platen glass and got a blurry mess. The edge marks are not sharp (I know steel is not transparent but there is enough light at the edges to scan). This proves that the Epson 3200 has two focus points - one for flatbed mode and one for transparency mode.

So decided to determine exactly how high up off the platen is the focus point for transparency mode. I did some research and found that the Epson film holders are supposed to be 1mm above the platen (correct or not?). So I set up some tests. I decided to use precision feeler gauges to put the steel string action gauge at 1mm above the glass and then scan it. In theory it should be as sharp as the flatbed scan.

I used a new set of gauges that were very oily so I separated them and washed them using Dawn dish soap to keep oil off the platen.

I used the 0.80mm plus the 0.20mm gauges to place the string gauge on the platen at 1.00mm

Here's what I got:

The image is soft. So the focus is off in transparency mode.

I then placed one edge of the sting gauge on the glass and put the other end at 1.50mm above the glass so it is angled up and past 1mm in height. I then scanned it to figure out if the focus point was above or below the 1.00mm point. It was well past 1.00mm.

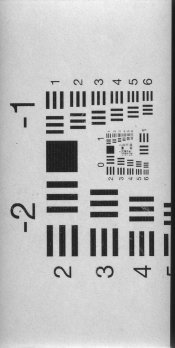

I won't bore you with all the empirical scans I did to figure out the focus point but here is the one at 1.33mm above

the glass:

I think this is about as good as it will get. The transparency scan focus point is set at 1.33mm.

Great. So how do I fix it? I suspect that there is some adjustment that the factory did to set the lens focus but I am not eager to open up the scanner and start turning screws blindly. Epson must have had special tools to do this in a production mode. I have come up with three options:

1. Shim up the negative holders by 0.33mm and use ScanTech SuperGlass™ ANTI NEWTON RING (ANR) Precision glass sheets to hold the 120 negatives flat. Doesn't solve my need to scan 70mm 127, and 617 negatives as I can't find negative holders for these sizes. And I need to find a 120 film holder to start with.

2. Use two sheets of ANR glass to hold the negative between them and shim the bottom glass to be 1.33mm high and just place in on the platen glass.. I don't know if I can get thin ANR glass that is 1mm thick or less. But if possible I could easily scan anything to include 617 negs, 120, 70mm, 127 (46mm) and 4x5 film. I use a glass negative holder for enlarging so cleaning the 4 sides of the glass holder doesn't bother me.

3. Use a single piece of ANR glass to hold the negative flat on the platen and software control to put the 3200 in flatbed focus mode but have the transparency light on. I don't know if this is possible. But I wonder why this isn't an option with flatbed scanners in the first place.

What is the most practical path forward? I won't bother using this scanner if I can't get sharp scans from it.

Thanks!

I scanned a couple of 35mm slides with the Epson 3200 but they were not very sharp. I suspected that I had a focus issue. I have an old 35mm Minolta Dimage Scan Speed SCSI scanner that is a lot sharper.

I did a flatbed scan of my stainless steel guitar string gauge (yeh I also work on guitars

) as it is flat and won't flop around like film does. The scan is extremely sharp:

) as it is flat and won't flop around like film does. The scan is extremely sharp:

I scanned it at 3200 DPI to a TFF file & converted it to jpg & reduced for posting here. No complaints with the flatbed mode scan.

I then did a scan in transparency mode B&W with the string action ruler lying on the scanner platen glass and got a blurry mess. The edge marks are not sharp (I know steel is not transparent but there is enough light at the edges to scan). This proves that the Epson 3200 has two focus points - one for flatbed mode and one for transparency mode.

So decided to determine exactly how high up off the platen is the focus point for transparency mode. I did some research and found that the Epson film holders are supposed to be 1mm above the platen (correct or not?). So I set up some tests. I decided to use precision feeler gauges to put the steel string action gauge at 1mm above the glass and then scan it. In theory it should be as sharp as the flatbed scan.

I used a new set of gauges that were very oily so I separated them and washed them using Dawn dish soap to keep oil off the platen.

I used the 0.80mm plus the 0.20mm gauges to place the string gauge on the platen at 1.00mm

Here's what I got:

The image is soft. So the focus is off in transparency mode.

I then placed one edge of the sting gauge on the glass and put the other end at 1.50mm above the glass so it is angled up and past 1mm in height. I then scanned it to figure out if the focus point was above or below the 1.00mm point. It was well past 1.00mm.

I won't bore you with all the empirical scans I did to figure out the focus point but here is the one at 1.33mm above

the glass:

I think this is about as good as it will get. The transparency scan focus point is set at 1.33mm.

Great. So how do I fix it? I suspect that there is some adjustment that the factory did to set the lens focus but I am not eager to open up the scanner and start turning screws blindly. Epson must have had special tools to do this in a production mode. I have come up with three options:

1. Shim up the negative holders by 0.33mm and use ScanTech SuperGlass™ ANTI NEWTON RING (ANR) Precision glass sheets to hold the 120 negatives flat. Doesn't solve my need to scan 70mm 127, and 617 negatives as I can't find negative holders for these sizes. And I need to find a 120 film holder to start with.

2. Use two sheets of ANR glass to hold the negative between them and shim the bottom glass to be 1.33mm high and just place in on the platen glass.. I don't know if I can get thin ANR glass that is 1mm thick or less. But if possible I could easily scan anything to include 617 negs, 120, 70mm, 127 (46mm) and 4x5 film. I use a glass negative holder for enlarging so cleaning the 4 sides of the glass holder doesn't bother me.

3. Use a single piece of ANR glass to hold the negative flat on the platen and software control to put the 3200 in flatbed focus mode but have the transparency light on. I don't know if this is possible. But I wonder why this isn't an option with flatbed scanners in the first place.

What is the most practical path forward? I won't bother using this scanner if I can't get sharp scans from it.

Thanks!

Last edited: