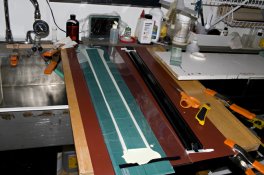

I wrote earlier I'm building a 35mm perforator from scratch. It works quite well for acetate, but may not be for great importance even if I posted instructions how to make one, as it will be a project that takes much time and requires tools not available for everyone.

Instead, I have found a simple and easy medium- or low-cost solution for a hobbyist to perforate our own film coatings. Whereas I found out that products sold as "35mm perforators" are very expensive special products, there are 35 mm motion print splicers that are actually meant for joining film ends together with tape, but some of them have perforator pegs to perforate through the tape. Correct search term is "35 mm splicer".

The one I bought from the USA was Dr. Leo Catozzo model available on Ebay quite often. You don't have to pay so much for them if you wait for good deals, but I was able to get one very quickly for 150 USD. I know they go for less every now and then. Note that all 35 mm splicers do not have the perforators, but at least the Catozzo model does.

This one does 5 adjacent perforations at a time. For perforating non-perforated film, registration pins from either side should be removed, which is very easy to do. Then, the actual perforating can be done in dark and is quite quick and easy to do with nitrile gloves etc.

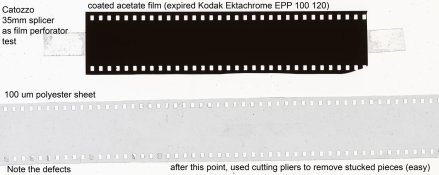

I have attached a scan of polyester sheet (the same I have coated on) and an acetate film (cut from 120 Ektachrome film) perforated with this tool.

Polyester is hard to perforate perfectly, but remaining pieces can be cut off with small cutting pliers or scissors.

A bigger version of scan is available at http://www.students.tut.fi/~alhonena/splicer_big.jpg

Instead, I have found a simple and easy medium- or low-cost solution for a hobbyist to perforate our own film coatings. Whereas I found out that products sold as "35mm perforators" are very expensive special products, there are 35 mm motion print splicers that are actually meant for joining film ends together with tape, but some of them have perforator pegs to perforate through the tape. Correct search term is "35 mm splicer".

The one I bought from the USA was Dr. Leo Catozzo model available on Ebay quite often. You don't have to pay so much for them if you wait for good deals, but I was able to get one very quickly for 150 USD. I know they go for less every now and then. Note that all 35 mm splicers do not have the perforators, but at least the Catozzo model does.

This one does 5 adjacent perforations at a time. For perforating non-perforated film, registration pins from either side should be removed, which is very easy to do. Then, the actual perforating can be done in dark and is quite quick and easy to do with nitrile gloves etc.

I have attached a scan of polyester sheet (the same I have coated on) and an acetate film (cut from 120 Ektachrome film) perforated with this tool.

Polyester is hard to perforate perfectly, but remaining pieces can be cut off with small cutting pliers or scissors.

A bigger version of scan is available at http://www.students.tut.fi/~alhonena/splicer_big.jpg

.

.