Photo Engineer said:

Mr. Gainer, well said. I agree for with the following qualification. If you remain within a given manufacturers products such as Ilford, then there is a great probability that all grade 2 papers (contact and enlarging both) will have the same toe and shoulder. This is due to the nature of the definition of the aim and physical and chemcial laws coupled with the coating process. If you use a Kodak product with the same grade, the mid scale will (must?) be the same due to the ANSI definition of 'grade 2', but the toe and shoulder may differ due to those same physical and chemical laws accouting for the manufacturing process and chemical differences between manufacturers.

Inventory and testing procedures within a given manufacturer lead to this sort of behavior. They try to use common chemicals across products for similar purposes, and these tend to lead to the same toe and shoulder curves.

PE

Not to be contentious but hoping to be informative, I found my copy of the 1982 Kodak publication. "Quality Enlarging with Kodak B/W Papers". I quote from the portion dealing with use of spot metering:

"METERING FOR PAPER CONTRAST

By measurement of a diffuse highlight area and a shadow area of the negative image projected onto the easel, and finding the difference, the proper contrast of paper for the image can be found.

When the log-illuminance range of the image matches the log-exposure range of the paper, the paper will print the image with acceptable contrast."

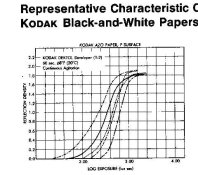

There is no mention in this publication of the use of the slope of the linear part of the characteristic curve as a measure of contrast grade. The log-exposure ranges of the various paper grades are expressed as the difference between the values required to produce 0.9 Dmax and 0.04. It is quite obvious from the diagrams that these diffuse highlight and shadow points are well out on the non-linear part of the curve.

An examination of the characteristic curves shows that in fact a number of the papers have no appreciable straight portion. As of 1982, the toe and shoulder gradations of these papers are not any more likely to be like one another than to be like the curves of another manufacturer. The curves for AZO show why the AZO afficionados prefer grade 3 over grade 2. The difference in curve shape is rather large, as is the difference in Dmax.

The papers available now may be much more alike. If they were all alike, there would be no need for more than one general type. I am sure that if the manufacturers could lead us in that direction, it would be an economy for them. Perhaps it would not be such a bad thing for us, but then we might say the same thing about the move from silver to digital. Even so, we will still cry about it.

I'm going on 78 years of age, so I hope you understand why I wax nostalgic.