This has been my quarantine project: building a horizontal 8x10 enlarger with a LED light source.

I have been (or still am?) on a steady quest for larger format negatives mostly for Pd/Pt printing. So last Christmas I got an Intrepid 8x10. Once I had some nice 8x10 negatives, I felt an urge to make large silver prints. It is also was clear that a vertical 8x10 enlarger would not fit into my darkroom space.

LED light source: Approximately 150 3W LEDs on a 12x12 aluminum heatsink

40 red, 50 blue and 60 green LEDs. They're stuck to the heat sink using double sided heat conducting tape. They are driven by Meanwell LDD-H 700mA drivers (12 altogether) and wired such that the central area can be controlled separately from the outside area. The drivers are PWM controlled by an Arduino Mega, which also conveniently serves as timer. I added a NTC thermometer in the center of the heatsink, so that it can switch itself off if gets to 60C, which given the thermal resistance of the LED base should correspond to a temperature of 110C at the junction. The fully assembled light source can run for ca. 15 minutes at full steam before it reaches that point.

For diffusion I use two layers of rosco diffuser 6 inches from the LEDs, which gives a very uniform light distribution of better than 1/3 of a stop corner to corner of 12x12 square inches. Also the inside of the LED box is coated with aluminum foil for reflection, to avoid light fall-off at the edges. The blue LEDs are not quite blue enough and so I get grades from 00-4. Printing times are quite uniform across the paper grades so 50/60 blue/green LEDs works.

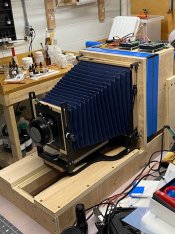

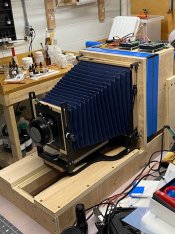

The enlarger body is made of 3/4 inch birch plywood and my first major table saw project. I use my Intrepid 8x10 for the front standard, bellows and focusing; but the body is built such that I can replace those with custom parts later on.

The lower left shows nicely the focusing rail for a later upgrade. The whole contraption sits on my main table and projects onto an easel (4x4 plywood) screwed to a sturdy storage shelf. With a 300m lens I need 60 inches distance to achieve a 4-fold enlargement to 32x40. At that size I have about 1/2 stop light fall-off in the corner, which I hope to reduce by tuning down the center section of the light source.

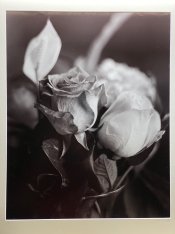

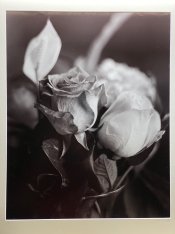

I managed to get my first 16x20 print done yesterday (still a 4-fold enlargement, I cropped

the image). Printing time is 40s at f32.

My 42 inch wide roll of paper is supposed to arrive sometime next week, dealing with those print will be its own set of challenges. In any case, so far so good. Loads of fun and challenges.

I have been (or still am?) on a steady quest for larger format negatives mostly for Pd/Pt printing. So last Christmas I got an Intrepid 8x10. Once I had some nice 8x10 negatives, I felt an urge to make large silver prints. It is also was clear that a vertical 8x10 enlarger would not fit into my darkroom space.

LED light source: Approximately 150 3W LEDs on a 12x12 aluminum heatsink

40 red, 50 blue and 60 green LEDs. They're stuck to the heat sink using double sided heat conducting tape. They are driven by Meanwell LDD-H 700mA drivers (12 altogether) and wired such that the central area can be controlled separately from the outside area. The drivers are PWM controlled by an Arduino Mega, which also conveniently serves as timer. I added a NTC thermometer in the center of the heatsink, so that it can switch itself off if gets to 60C, which given the thermal resistance of the LED base should correspond to a temperature of 110C at the junction. The fully assembled light source can run for ca. 15 minutes at full steam before it reaches that point.

For diffusion I use two layers of rosco diffuser 6 inches from the LEDs, which gives a very uniform light distribution of better than 1/3 of a stop corner to corner of 12x12 square inches. Also the inside of the LED box is coated with aluminum foil for reflection, to avoid light fall-off at the edges. The blue LEDs are not quite blue enough and so I get grades from 00-4. Printing times are quite uniform across the paper grades so 50/60 blue/green LEDs works.

The enlarger body is made of 3/4 inch birch plywood and my first major table saw project. I use my Intrepid 8x10 for the front standard, bellows and focusing; but the body is built such that I can replace those with custom parts later on.

The lower left shows nicely the focusing rail for a later upgrade. The whole contraption sits on my main table and projects onto an easel (4x4 plywood) screwed to a sturdy storage shelf. With a 300m lens I need 60 inches distance to achieve a 4-fold enlargement to 32x40. At that size I have about 1/2 stop light fall-off in the corner, which I hope to reduce by tuning down the center section of the light source.

I managed to get my first 16x20 print done yesterday (still a 4-fold enlargement, I cropped

the image). Printing time is 40s at f32.

My 42 inch wide roll of paper is supposed to arrive sometime next week, dealing with those print will be its own set of challenges. In any case, so far so good. Loads of fun and challenges.