elgatosuizo

Member

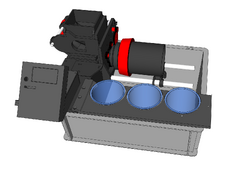

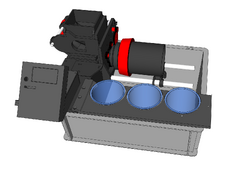

This summer I completed my self-designed RA-4 film processor, and that was the ignition point for an older idea:

to build a small, semi-automatic rotary film processor in the spirit of the classic Jobo CPE/CPP series —

but 3D-printed, stepper-driven, and compact enough to fit in half a Eurobox (30 × 40 cm).

Originally, I discovered a nice build on Printables by @Franktion_442763 and thought I’d start from there.

But the STL files were difficult to modify (and used a DC motor, while I prefer steppers).

So I decided to redraw the entire design, and one idea led to another —

a motorized lift, automatic rinse control with a small pump, and a smart controller to orchestrate the process.

Eventually, I had moved completely away from the original model — except for the Eurobox footprint.

So, full credits to Franktion_442763 (and others who inspired DIY Jobo-style builds).

I moved to an Arduino Mega 2560 Pro for control and a Nano dedicated to the steppers, linked via serial.

The flowmeter proved unreliable due to noise, so I now calculate volumes by calibrated pump time — works great.

Each component is isolated and filtered for reliability, and the firmware supports 7 process profiles with up to 12 steps each.

However, I’ve noticed a few small details to refine:

honestly beyond my expectations — and in terms of workflow and warm-up handling,

it’s surprisingly close to a real Jobo CPP.

Here some more Details on the mechanics:

I also recorded a demo video, which I’ll post soon.

to build a small, semi-automatic rotary film processor in the spirit of the classic Jobo CPE/CPP series —

but 3D-printed, stepper-driven, and compact enough to fit in half a Eurobox (30 × 40 cm).

Originally, I discovered a nice build on Printables by @Franktion_442763 and thought I’d start from there.

But the STL files were difficult to modify (and used a DC motor, while I prefer steppers).

So I decided to redraw the entire design, and one idea led to another —

a motorized lift, automatic rinse control with a small pump, and a smart controller to orchestrate the process.

Eventually, I had moved completely away from the original model — except for the Eurobox footprint.

So, full credits to Franktion_442763 (and others who inspired DIY Jobo-style builds).

Design goals

- Semi-automatic operation: automatic rotation, chemical dumping, and water rinse.

(I skipped full automation with chemical pumps — too much cleaning afterward!) - Compatibility: supports C-41, E-6, and B/W workflows.

- Heating: done via Sous-Vide immersion heaters, a proven and simple solution.

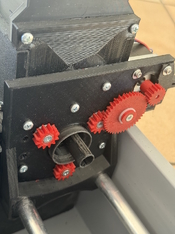

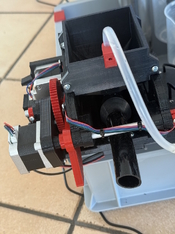

- Mechanics:

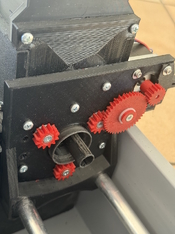

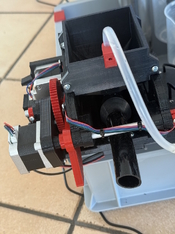

- Stepper-driven drum rotation with three small gears centering the Jobo tank gear.

- Stepper-driven lift with reduction gearing for torque.

- Two-liter integrated rinse-water tank under the mechanism, thermally coupled to the main bath.

- Three temperature sensors: one in the water bath, one in the rinse tank, and one handheld probe for chemicals.

Electronics

After some early struggles (ESP32 was unstable with steppers + keypad),I moved to an Arduino Mega 2560 Pro for control and a Nano dedicated to the steppers, linked via serial.

The flowmeter proved unreliable due to noise, so I now calculate volumes by calibrated pump time — works great.

Each component is isolated and filtered for reliability, and the firmware supports 7 process profiles with up to 12 steps each.

First test results

The first full development cycles have run almost perfectly.However, I’ve noticed a few small details to refine:

- The wide-mouth beakers I used aren’t ideal for temperature control.

I’ve already drawn and 3D-printed three custom lids to improve chemical pre-heating in the water bath. - The drain outlet drips slightly, so that needs a small redesign.

- The mantle bath can’t heat cold rinse water efficiently,

but if you fill it already at the correct temperature, everything stays perfectly stable. - To pre-warm developer and blix, I simply place their closed bottles in the water bath before pouring into the beakers.

honestly beyond my expectations — and in terms of workflow and warm-up handling,

it’s surprisingly close to a real Jobo CPP.

Here some more Details on the mechanics:

I also recorded a demo video, which I’ll post soon.