Hi all. I'm in the process of resurrecting a Yashica Mat TLR with a Copal MXV shutter. The camera exterior is in need of some TLC but the main issue is the shutter speeds - all of the speeds under 1/500 are slow. From my research around it seems like this issue can be fixed by cleaning the speed escapement in the shutter (flushing out with 99.9% Isopropyl alchohol + ultrasonic cleaning) - however my issue is that i am unable to remove 2/3 of the slotted screws that hold it in place: they just wont budge and cause my screwdriver to cam out and strip the top of them, but one screw comes out just fine.

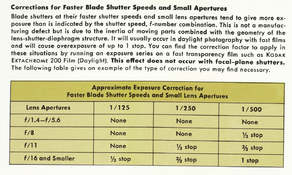

I had some real issues with the brass slotted screws on the exterior of the camera being similarly stiff but was able to force them loose with more pressure and an application of wd-40 to them overnight, however I really don't want to do any of that to these fragile shutter mechanisms. I am using a Wera 0.3x1.8mm screwdriver and whilst it doesn't fill the entire width of the slotted screw it works perfectly on one of them and in this () video it is used effectively to remove these exact screws.

Any advice on how to get these two screws loose would be much appreciated, for reference it is the outer two screws in this photo that won't budge. Would a very very very sparing application of penetrating oil work, or perhaps a soldering iron to heat the screw? Or is it a lost cause? Would love to hear people's thoughts!

Thanks