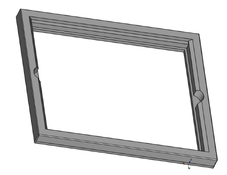

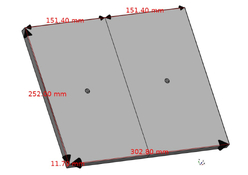

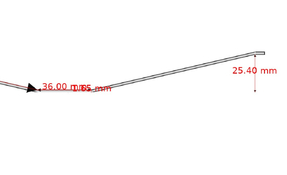

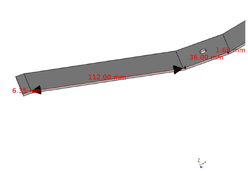

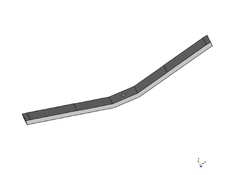

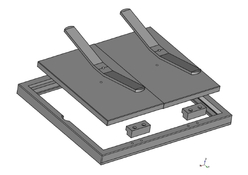

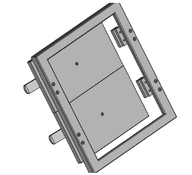

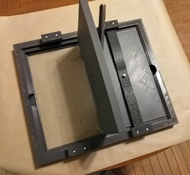

This is a new thread based on the linked thread, where this project originated. A new thread was decided upon for the highest visibility in the search engines. While I have not actually printed one, I have made test prints of sections, just to check for fit. I'm confident users will be able to print one out and use it. If there are complaints, please post them here. This was done in Freecad 21.2. These are stl files only, along with the PDF exports converted to JPEG for the woodworkers out there, although I strongly urge that it not be done in woodwork. The long and short rails are entirely different. On a Neptune 4 Max printer it requires only 15 1/2 hours for the frame alone, with a 50% infill with PETG filament. The glass is 3/32 ordinary picture frame glass, size 10 x 12 exactly. Since this frame is most likely to be taken out in the bright hot sun, DO NOT use PLA as it will surely melt. I'm sorry I couldn't post the actual Freecad files so that users could make changes, but apparently Freecad files won't zip. Measurements of my original antique Century 10 x 12 frame were taken on a metric Mitutoyo dial caliper. Moderators are asked to move the thread to wherever highest search engine visibility will allow

Linked original thread:

www.photrio.com

www.photrio.com

PS. Print frame backside up. No support or brim

{Moderator's edit - see post #25 for updated STL files}

Linked original thread:

Making a printing frame

I made a printing frame for less than $10 using these two components: A...

PS. Print frame backside up. No support or brim

{Moderator's edit - see post #25 for updated STL files}

Attachments

Last edited by a moderator: