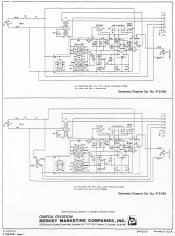

Hey all, I recently inherited a Chromegatrol (version 412-040) power supply and timer for Super Chromega D enlarger that is exhibiting the classic symptoms of a problem with the timing circuit: the enlarging bulb doesn't light and the unit emits a strange buzz. I opened the thing up and looked for obvious damage but it actually seems pretty clean inside. I ended up labeling all the connections and pulling the board so that I can check/replace all of the components (starting the with the big electrolytic capacitor), but I'm wondering if anyone who has done this repair has any suggestions for a specific culprit. I took a video of the behavior (http://ur.sine.com/temp/PXL_20210225_040409931.mp4) so you can see what's going on. I'm also puzzled about the big aluminum cylinder (in the bottom right of the first image) in the housing. Is it a relay? A giant capacitor? I think it's labeled on the schematic as DS1 and DS2 (never mind I realized these are the indicator lamps, so I have no idea where it is on the schematic), since I don't see anything else on there it could be, but the symbol is equally inscrutable. Any help or advice is appreciated!

Attachments

Last edited: