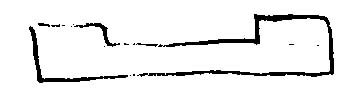

I've been thinking of ways to stiffen the base of my 1890s lightweight 11x14" field camera, and I was considering routing 4 channels crosswise and epoxying carbon fiber rods that are used to stiffen guitar necks in them.

I was planning to use these 0.200" x 1/4" x 18" rods--

http://www.stewmac.com/shop/Truss_rods/Carbon_fiber/1/Carbon_Fiber/Details.html#details

Has anyone tried this, and does it seem like a good plan?

I was planning to use these 0.200" x 1/4" x 18" rods--

http://www.stewmac.com/shop/Truss_rods/Carbon_fiber/1/Carbon_Fiber/Details.html#details

Has anyone tried this, and does it seem like a good plan?