1) would you mind elaborating on what problems dumping my working tank can be introducing?

If you mixed the developer tank solution correctly (replenisher, starter & water) then there should be no need to dump. Remember what I said about letting the tank solution "settle". Am I correct in that the negatives look and scan OK but the densitometer reading is off and that's why you dump the chemicals?

2) Xright 810 - calibrated

Great.

3) yes they are stored cold

Great.

4) sometimes I don't wait as long as I could. I'll run a new set of test strips with all fresh chemicals and see what I get nd report back here

Good.

5) I do not record my CD temperature and log it. What benefits will I gain from doing so?

The benefit is that you have a record of the temperature of the developer over time. Information is always helpful and if consistent (when viewed on a chart or log) can eliminate temperature as a cause of a problem.

I would recommend a weekly log of control strips, developer temperature readings, all tanks replenishment rates and pump output.

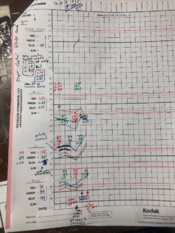

6) I do. I follow kodaks procedure on z131 with fuji's control strips and graph everything on a kodak graph

Good.

7) I keep awareness of the replenisher pumps, and I've uploaded a video of the CD circulation pump (all the others are fine, but please let me know if you think the CD is fine in the video. (read reply above for link to video)

Circulation looks good. The tank looks full even with the rack taken out. Normally it should look just over half full with the rack out. Also the machine should alarm when the rack is out and the levels drop. The circulation should then stop and heater cut out. Did it do this?

Am I viewing that correctly and why is it looking full?

8) it has not been serviced or calibrated since I purchased it a year ago in very good condition

I would recommend that the machine should be serviced at least once a year by a Noritsu engineer (if possible).

MY TEST STRIPS HAVE NEVER BEEN IN ORDER SINCE I SWITCHED TO FUJI. EVEN WHEN MIXING NEW CHEMICALS, MY PLOTTINGS ARE OFF THE CHARTS. INFACT THE CORRECTION FACTORS MAKE EVERYTHING WORSE - DESPITE THIS THE FILM COMES OUT VERY NICELY. GREAT CONTRAST, VIBRANCE, AND COLORS

I think your problem may be here. I think something is causing incorrect readings.

Can you get another densitometer, borrow from someone, and compare readings? Or could you send your control strips to someone that can make reliable readings for you. (Fuji in Ireland offered this service years ago)

The X-Rite 810 recommends you do the transmission calibration weekly. Do you do this?

Is the opal glass cleaned regularly and the optic blown with compressed air to free any dust?

Incase you haven't the X-Rite manual, here it is.

X-Rite 810 manual

Reading the chart: First how many films (on average) do you process?

Your Noritsu V30 has a 7.6 Liter tank so look at the row 10L. At the bottom is the number of films processed per day. I have high lighted in blue in the chart.

If you process 10 films a day (on average) then you should be using (yellow 1) EnviroNeg Developer Replenisher 60AC @ 60ml per 35mm 24 exp film.

If you process 15 films a day (on average) then you should be using (green 2) EnviroNeg Developer Replenisher AC.

One last note. Do you remove the cross over racks, in sequence, every night and put them in a water bath (a 10x8 print tray filled with water or something similar)?

Do you leave the top cover/lid of the machine slightly open/vented to stop condensation from forming on the inside of the lid?

I hope this helps. It would be great if you could get someone local to you, with the relevant knowledge, to help.

Be prepared to pay for this knowledge. Ideally a Noritsu C41 service engineer, they would be worth their weight in gold and probably as rare as hen's teeth.