So I'm planning to start manual processing films myself using Fujifilm C-41RA chemistry (intended for minilabs).

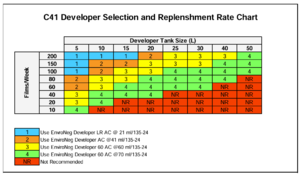

I have read every technical paper I could find and I'm now aware that the replenishing rates of the chemistry are also dependent on the working tanks volumes, but there was nowhere I could find a guideline for a proportion of replenishing volume vs tank volume. There is just no mention on Fujifilm nor on Kodak C-41 chemicals technical sheets other than recognizing it as a factor, but no numbers or whatsoever. I guess that a minilab tank size is expected, but they do come in different sizes (5-10L i think). Overreplenishing is mentioned as a problem. This is my main concern as my working tank will likely be small (1L) so as not too waste much when re-mixing new tanks (a tradeoff for consistency). If I were to replenish say 50ml for each roll as suggested by the technical sheet, I'm sure I'll have an overreplenished tank pretty soon. On the other hand, underreplenishment is obviously a problem, too. The developer is the only solution to be concerned. The one that's available where I live is one you get by mixing a starter with a replenisher that comes as a single solution, and water.

It seems that Fujifilm hasn't published a detailed guide as Kodak's old "131" pdf. There are a few guides they published, all of which I found incomplete, outdated, not meant for the exact same chemistry they sell today.

Before getting dissuasive advice I just want to say the following: I'm aware there are so many things to consider, so much to put together from the notes I've been taking during the past weeks before I proceed to buy the stuff. Perpetuating a working tank solution is not the plan, but a repetitive replenishing cycle for some time before mixing a new working tank is needed to make this economically feasible where I live (prices are 4x the US prices for this chemistry). I know there is no definitive guideline, and that exhaustive testing of solutions with test strips has to be done periodically to get consistent, high quality results. (Minilab tanks will deviate from acceptable concentrations even when following the datasheets by the letter and having a high throughput. If complete testing can't be run the best thing to do is to discard and mix new working tanks from time to time). I just need a good guess to start with, an educated guess for this 'replenishing rate:tank volume' ratio. I won't be using test strips and a densitometer, at most I will do pH and SpG metering. I don't expect optimal processing, though I want it to be quite good. To have my films processed by local labs is not only expensive, but unacceptable to my quality standards. There's really no other option than doing it myself. Rigorous storage of chemicals will be carried out. It is likely that the chemicals will be split between some friends and I so as not to waste much due to expiration and oxidation, and it's also likely for me to start offering film processing services where I live.

I'll be happy to share my procedure in detail if I get to make it work. Any help will be appreciated!

I have read every technical paper I could find and I'm now aware that the replenishing rates of the chemistry are also dependent on the working tanks volumes, but there was nowhere I could find a guideline for a proportion of replenishing volume vs tank volume. There is just no mention on Fujifilm nor on Kodak C-41 chemicals technical sheets other than recognizing it as a factor, but no numbers or whatsoever. I guess that a minilab tank size is expected, but they do come in different sizes (5-10L i think). Overreplenishing is mentioned as a problem. This is my main concern as my working tank will likely be small (1L) so as not too waste much when re-mixing new tanks (a tradeoff for consistency). If I were to replenish say 50ml for each roll as suggested by the technical sheet, I'm sure I'll have an overreplenished tank pretty soon. On the other hand, underreplenishment is obviously a problem, too. The developer is the only solution to be concerned. The one that's available where I live is one you get by mixing a starter with a replenisher that comes as a single solution, and water.

It seems that Fujifilm hasn't published a detailed guide as Kodak's old "131" pdf. There are a few guides they published, all of which I found incomplete, outdated, not meant for the exact same chemistry they sell today.

Before getting dissuasive advice I just want to say the following: I'm aware there are so many things to consider, so much to put together from the notes I've been taking during the past weeks before I proceed to buy the stuff. Perpetuating a working tank solution is not the plan, but a repetitive replenishing cycle for some time before mixing a new working tank is needed to make this economically feasible where I live (prices are 4x the US prices for this chemistry). I know there is no definitive guideline, and that exhaustive testing of solutions with test strips has to be done periodically to get consistent, high quality results. (Minilab tanks will deviate from acceptable concentrations even when following the datasheets by the letter and having a high throughput. If complete testing can't be run the best thing to do is to discard and mix new working tanks from time to time). I just need a good guess to start with, an educated guess for this 'replenishing rate:tank volume' ratio. I won't be using test strips and a densitometer, at most I will do pH and SpG metering. I don't expect optimal processing, though I want it to be quite good. To have my films processed by local labs is not only expensive, but unacceptable to my quality standards. There's really no other option than doing it myself. Rigorous storage of chemicals will be carried out. It is likely that the chemicals will be split between some friends and I so as not to waste much due to expiration and oxidation, and it's also likely for me to start offering film processing services where I live.

I'll be happy to share my procedure in detail if I get to make it work. Any help will be appreciated!

Last edited: