Also how far would the pinhole have to be away from the film?Any idea what size pinhole I would need for 6 x 9 120?

-

Welcome to Photrio!Registration is fast and free. Join today to unlock search, see fewer ads, and access all forum features.Click here to sign up

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Pinhole Camera

-

A

- Thread starter WGibsonPhotography

- Start date

Recent Classifieds

-

Sold Intrepid 4x5 Black Edition

- Started by Jessxi

-

For Sale 35mm black and white film. 17 rolls

- Started by Simon Benton

-

For Sale STEARMAN SP-8x10+ DAYLIGHT SHEET FILM PROCESSING SYSTEM.

- Started by Simon Benton

-

For Sale Original Canon F1 professional camera, two lenses.

- Started by summicron1

-

Sold Phochron XA shutter tester

- Started by OrientPoint

Forum statistics

I have one more question: Would balsa wood be an appropriate material to make a pinhole camera out of (painted, of course)? I think I can get sheets of it at a local crafts store.

As BetterSense wrote, balsa may not be light tight enough, but that's only a secondary consideration. Blacking it out with surface coatings is easy enough. A couple of coats of primer and flat black paint will fix that. But balsa is pretty flimsy stuff, and cameras get knocked around a lot. Not a good combination. Basswood might be a bit better.

PINHOLE SIZES

Mrpinhole.com is what I used...

It calculates it for you.

here's another cool site..

http://www.corbis.readymech.com/en

You can spend a fortune on laser drilled pinholes...and if you have money to spend...go ahead,

but if you are building a pinhole, go to ace hardware and buy a sheet of (.003) brass... and dimple and sand the hole to the size you need. I used a #10 "between" needle..which was about .017" perfect from the 102mm focal length.

I built my whole camera out of black foam poster board and used instant glue and hardener from the model airplane shop.

The camera is a 4x5, and takes pretty good shots. I have posted some in my gallery.

Here is the link to what and how I built it.

http://gallery.me.com/kb2qqm#100294

Yea, it's foam...but it works pretty good.

It is the Earl Johnson special from over on f295.org

Here's the first shot...

Greg

Mrpinhole.com is what I used...

It calculates it for you.

here's another cool site..

http://www.corbis.readymech.com/en

You can spend a fortune on laser drilled pinholes...and if you have money to spend...go ahead,

but if you are building a pinhole, go to ace hardware and buy a sheet of (.003) brass... and dimple and sand the hole to the size you need. I used a #10 "between" needle..which was about .017" perfect from the 102mm focal length.

I built my whole camera out of black foam poster board and used instant glue and hardener from the model airplane shop.

The camera is a 4x5, and takes pretty good shots. I have posted some in my gallery.

Here is the link to what and how I built it.

http://gallery.me.com/kb2qqm#100294

Yea, it's foam...but it works pretty good.

It is the Earl Johnson special from over on f295.org

Here's the first shot...

Greg

Last edited by a moderator:

- Joined

- May 17, 2006

- Messages

- 948

- Format

- Medium Format

pinhole calculator for the MAC

http://www.concepthouse.com/products/PinholeCalc/

(Mac software-works on my intel mac)

Greg

http://www.concepthouse.com/products/PinholeCalc/

(Mac software-works on my intel mac)

Greg

Also how far would the pinhole have to be away from the film?

My 6x9 is 60mm focal length using a .3mm pinhole. Works fine

My 6x9 is 60mm focal length using a .3mm pinhole. Works fine

Thanks for the reply. How would be the best way to go about making this pinhole? I do have access to an engraving laser.

Ive made quite good holes using a coke can a pin and 1200 grit sanding paper. .3mm is quite easy, but I use EMS laser pinholes that a friend form the US sent me. Will the laser you have access to do a single .3mm hole? if so get some thin brass or copper shimming material and whack a hole in it...

Here how to do your own http://withoutlenses.com/view/drill-your-own

Here how to do your own http://withoutlenses.com/view/drill-your-own

- Joined

- May 17, 2006

- Messages

- 948

- Format

- Medium Format

I would definitely try the engraving laser just to see if it can be done. What is the smallest spot you can make with that laser? Get some 0.001 inch thick brass or stainless steel shim stock and see if you can burn a tiny little hole. Last time I bought shim stock was from http://www.smallparts.com but since they turned into an Amazon store I have no idea if they still carry stuff like this. I would expect McMaster-Carr (http://www.mcmaster.com) will also have this, and maybe Dead Link Removed might have shim stock.

The thinner the metal, the better the pinholes. The brass will be fairly fragile so be careful. The stainless should be relatively robust (considering the thickness we are talking about).

The thinner the metal, the better the pinholes. The brass will be fairly fragile so be careful. The stainless should be relatively robust (considering the thickness we are talking about).

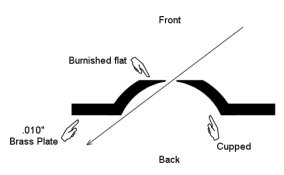

Attached is a generic plan for a pinhole design which I currently use. Being cupped outward allows you to burnish the plate down to minimal thickness at the pinhole. The thickness of the material that makes the pinhole is a critical parameter which is sometimes overlooked by the pinholer.

Another area that can be overlooked is that a pinhole that is too small is just as bad as a pinhole that is too big. That is, if you are concerned with image sharpness.

Cheers!

Another area that can be overlooked is that a pinhole that is too small is just as bad as a pinhole that is too big. That is, if you are concerned with image sharpness.

Cheers!

Attachments

Last edited by a moderator:

That's pretty much what you end up with when you use a needle and a pop can, too, if you follow the popular method of dimpling the can and sanding it with fine sandpaper.

To get 15.8 feet, I multiplied 746.5 by 10 to get 74.65cm. I then divided 74.65 by 2.54 to get 29.38in.

That should actually say "to get 29.38in." I was trying to correct a mistake in math by taking out the numbers I screwed up and replacing them with the right ones. I just now caught that I didnt get the first 15.8 feet part. The edit button wasnt under the post tonight, and I dont know why :/

Here you go, no math involved. Glued a board in a 1 gal. paint can to hold the paper negative flat. Sprayed the inside of the can with flat black paint. Drilled a hole in the can with a #72 drill bit (I think) and the sanded with 400 grit sand paper to remove the burrs and hopefully thin the metal a bit. Here a an image from the camera (contact print from paper negative). http://www.pinholeday.org/gallery/2008/index.php?id=382

Roger

Roger

| Photrio.com contains affiliate links to products. We may receive a commission for purchases made through these links. To read our full affiliate disclosure statement please click Here. |

PHOTRIO PARTNERS EQUALLY FUNDING OUR COMMUNITY:  |