OK, sounds good.

Most of the rubber bladders that they use for vacuum frames have a seal gasket in the perimeter. I don't think foam weatherstripping will work too well for two reasons

1. It may be somewhat fragile.

2. It might be permeable to air in a way that will cause the frame to leak all the time.

Look at this site:

http://bostick-sullivan.invisionzone.com/index.php?/topic/708-homemade-vacuum-frame/

There is a cross-sectional drawing that shows the basic assembly of MOST frames That I have seen. Basically, the glass is on top, then the print materials, and then the bladder behind. The bladder is supported underneath, but it essentially "sucks up" to the glass when under vacuum. Note that the drawing has the frame inverted with the light at the bottom, whereas most printers print with the light at the top.

I would consider rubber tubing as they used in the linked discussion, or look into rubber gasket or weatherstripping material. It should hold up better and produce a good seal on the glass.

Definitely put a bleeder valve in the line so that you can control the amount of vacuum you put on the print.

I don't know about in the UK, but here contact exposure frames are pretty easily found if you live in a metro area, so I wouldn't be building one without doing a little google searching for a print shop frame first. I only say that because I'd rather spend my time printing than making stuff for the darkroom!

My current frame in the Amergraph is a piece of glass on a hinge on top (no frame). The bottom is the rubber bladder with the built-in seal ring on the perimeter. It lays on a metal bed and the vacuum pulls down on the glass some, and then the bladder pulls up tight on the glass once the seal around the perimeter is compressed.

It never fails to pull, even with the bleeder valve set to produce a vacuum that isn't a full vacuum.

I can post some photos if you need some.

---Michael

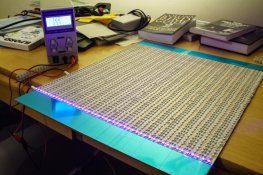

Now to make the vacuum frame!

Now to make the vacuum frame!