harlequin

Member

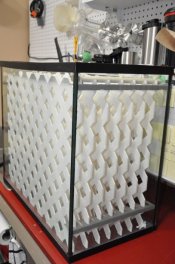

looking at prices of even used zone6 or calumet print washers made of clear acrylic, was wondering if anyone on apug fabricated one DIY mostly for 8/10 size and below, does not have to look like alistar ingless model from Canada, but was trying to build one if possible, maybe someone can share their experience either positive or negative, and what materials?

When I was a teenager I remember seeing one from Patterson, but it looked complicated....

Many Thanks!

Harlequin

When I was a teenager I remember seeing one from Patterson, but it looked complicated....

Many Thanks!

Harlequin