Well, I've almost finished my first pinhole camera. It's a 7.5 inch focal length camera made out of a birch plywood that I found at hobby Lobby. I just have one more step: making the pinhole. Since my math skills are comparable to the math skills of a drunk monkey, can someone check my numbers to make sure I havent missed something or screwed up some simple calculation?

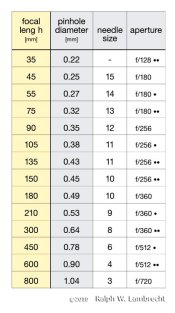

I'm using a formula that Ralph Lambrecht posted on a pinhole thread here, which is PinholeDiameter=sqrt( (2.44)(wavelength)(Focal Length) )

I found on a seperate website (cant remember where) that 5500Angstroms is the wavelength of average daylight, so I guess I'll go with that. That same website said 1Angstrom = 1nm, which is 0.00055mm, right?

To convert 7.5inches to millimeters, I multiplied 7.5 by 2.54 to get 19.05cm. I multiplied that by 10 to get 190.5mm.

i plugged the wavelength and focal length in millimeters in to the formula. Assuming I did my math right, the diameter should be about 0.5mm. Is that right? If not, could someone point me in the right direction?

BTW, I have some 5x7 HP5+ coming from Freestyle. Ihope to be taking pictures with it by this weekend :

I'm using a formula that Ralph Lambrecht posted on a pinhole thread here, which is PinholeDiameter=sqrt( (2.44)(wavelength)(Focal Length) )

I found on a seperate website (cant remember where) that 5500Angstroms is the wavelength of average daylight, so I guess I'll go with that. That same website said 1Angstrom = 1nm, which is 0.00055mm, right?

To convert 7.5inches to millimeters, I multiplied 7.5 by 2.54 to get 19.05cm. I multiplied that by 10 to get 190.5mm.

i plugged the wavelength and focal length in millimeters in to the formula. Assuming I did my math right, the diameter should be about 0.5mm. Is that right? If not, could someone point me in the right direction?

BTW, I have some 5x7 HP5+ coming from Freestyle. Ihope to be taking pictures with it by this weekend :

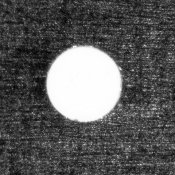

It's waaaay underesposed. It's my first try, though, so I'm not too disapointed.

It's waaaay underesposed. It's my first try, though, so I'm not too disapointed.