Korbel

Member

Hello, I decided to share my side project with the community.

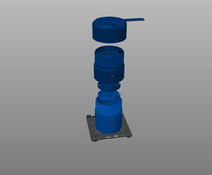

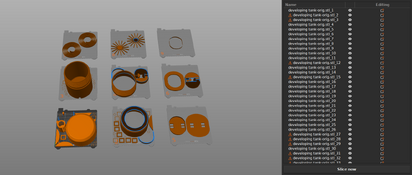

The price of the print was estimated on 300 euro, so I gave up on it. According to the printers the screwing mechanism isnt optimised for 3d plastic printing and the whole thing is untested. Hence some tweaking is needed.

The spools should be able to take both 120 and 220 films. My idea was to load one film from the inside and one from the outside so I could have two 120 films on one spool.

The black part is a light trap based on a Penrose's unilluminable room. I have tested it with blender for light leaks and it should be light proof while allowing liquids to pass. Better print accuracy is needed because it is an optical device. There is some compensation in form of two such light traps merged together.

From materials you should pick something resistant to acidic and alkalic substances.

When exporting for 3d print do scale by factor of 1000, the exports in printers software behaves funky.

marekkorbel.cz

marekkorbel.cz

Cheers!

The price of the print was estimated on 300 euro, so I gave up on it. According to the printers the screwing mechanism isnt optimised for 3d plastic printing and the whole thing is untested. Hence some tweaking is needed.

The spools should be able to take both 120 and 220 films. My idea was to load one film from the inside and one from the outside so I could have two 120 films on one spool.

The black part is a light trap based on a Penrose's unilluminable room. I have tested it with blender for light leaks and it should be light proof while allowing liquids to pass. Better print accuracy is needed because it is an optical device. There is some compensation in form of two such light traps merged together.

From materials you should pick something resistant to acidic and alkalic substances.

When exporting for 3d print do scale by factor of 1000, the exports in printers software behaves funky.

Download blender file here:Developing Tank – Marek Korbel

marekkorbel.cz

marekkorbel.cz

Cheers!

I know nothing of 3d printing so we can merge our powers. Or I can upload the STL files

I know nothing of 3d printing so we can merge our powers. Or I can upload the STL files