Herzeleid

Member

Approximately two months ago, I needed to find a way to neutralize the alkaline buffer in some papers so I could practice with the new cyanotype and the argyrotype processes. In this period I have tried various acids such as hydrochloric acid, citric acid and oxalic acid. I have experimented with sulfamic acid to use for paper acidification and neutralization process, which I believe to be a better choice of acid than the most.

I heard this acid for the first time in Mike Ware’s argyrotype formula. I am no chemist by the way, but I noticed that sulfamic acid is quite a strong acid when I tossed a spoonful of it into the sink (don’t ask why). Within less than a minute I heard that it started fizzing loud, I washed it away hastily. Then I have decided to read and learn about the sulfamic acid and its uses, because I needed an acid to neutralize the buffer in papers and sulfamic acid sounded (well, it fizzed) to be capable.

It seems that sulfamic acid is used in modern descaling systems instead of hydrochloric acid, due to its less corrosive and at the same time equally strong acidic nature. It is also used in paper industry as pulp bleach. It sounded quite ideal to me because of its use in paper making and less corrosive properties.

Let me list some of the advantages of sulfamic acid

I do not want to discuss in length problems with the other acids I tested for paper acidification, but suffice to say some of these problems forced me to look for an alternative. Sulfamic acid treatment causes no water insoluble solid byproduct inside the paper. There is no hazardous gas release during the process, or any respiratory irritant odor. It is cost effective and neutralizes the buffer completely with no loss of image quality.

Using sulfamic acid, I believe the treated papers become suitable for every alkaline sensitive siderotype, not just pt/pd and show no loss of dMax. I have tested various papers such as 300gsm Canson Montval, 420gsm Gvarro, 180gsm Schoellerschammer dura matt, 200gsm Fabriano Artistico Traditional White HP, 300gsm Fabriano Artistico Extra White SP, I happened to have a small piece of Hahnemühle Copplerplate warm white 300gsm and I also tested some cheap schoeller and alex drawing papers. All these papers were alkaline buffered and after treatment they all work well within expectations.

The acidification procedure is very simple and straightforward. I mixed 1M solution of Sulfamic Acid (97gr/mol), if you prefer it non-molar terms it is ca. %10 solution. 1 liter 1 molar solution of SA is approximately capable of neutralizing 50gr. of calcium carbonate. We can assume it would neutralize 20 sheet (56*76cm) paper’s buffer if we assume a sheet of paper contains 2 to 2,5gr of calcium carbonate (Thanks to Loris for providing me all these data on chemical equations and ISO9706 papers). To be safe use less number of papers, I assumed that 1lt 1M solution is capable of neutralizing 14 to 15 papers alkaline buffer safely. There is no need to emphasize the gloves and adequate ventilation, because it is always the right thing to do. Sulfamic acid is as strong as HCl, but less corrosive to metals.

I immersed the papers in SA solution for 15-20 minutes, flipping the paper 4-5 times during this wash. Of course, the length of this period will depend on the paper used. Loris noticed the reaction continues after 15minutes with 300gsm FAEW SP, and I observed the same. But with 300gsm Canson Montval, 420gsm Gvarro and 200gsm FATW HP the reaction seems to finish around 10-12 mins. Anyway, later I have decided to wash all these papers for 20minutes to be on the safe side, and I did not observe any adverse effects.

After acidification, I washed the papers (5 of them in the same tray) with tap water (chlorinated, not filtered, measured Ph. 7), for 20-25 minutes with 4-5 changes of water, and with each change of water shuffling the papers and bringing the bottom one to the top. When finished washing, I hanged the papers to dry in the bathroom.

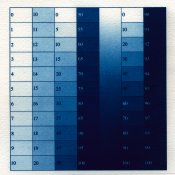

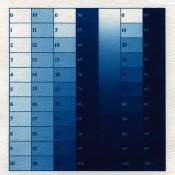

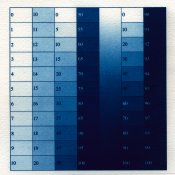

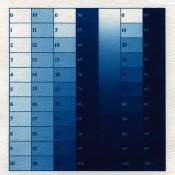

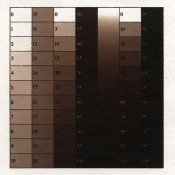

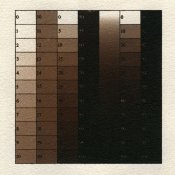

The New Cyanotype process: As expected the sensitizer does not require additional citric acid to use with SA treated papers. The papers become chemically pure enough for new cyanotype. Adding CA to sensitizer even lowers dMax and shifts the color slightly. I have left coated paper (without CA) due to power outage for more than 12 hours and there was negligible fogging (24C %60-65RH). The amount of ilfotol depends on the paper, but I have found for Canson Montval and FATW 1drop of ilfotol per ml, for FAEW SP 2drops of ilfotol per ml work best for me.

All the samples were produced in 25C %55RH environment, printed with UVBL bulbs using non-linearized image-setter negatives. Initial wash for 1 minute in %1 sulfamic acid, then washed in tap water for 20mins.

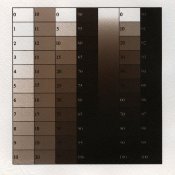

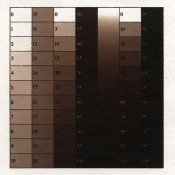

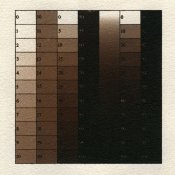

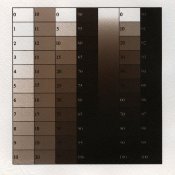

The Argyrotype process: It worked flawlessly IMO. The sensitizer requires surfactant by nature. I have found that double the amount of ilfotol I used for new cyanotype works well for argyrotype. After determining the correct amount of ilfotol/tween I have noticed no bleeding. FAEW SP is particularly a hard surfaced paper it requires moderate humidity and quite a lot of tween or ilfotol in the sensitizer. For comparison I also included a sample printed on Masa paper, it works with new cyanotype, argyrotype and ziatype without any prior acid treatment.

All the samples were printed in 25C %55RH environment with UVBL bulbs using non-linearized image-setter negatives. Initial wash in %0.25 citric acid for 3minutes, %3 hypo for 1 min, then tap water 20mins.

Sulfamic acid treated papers work very well with the new cyanotype and argyrotype processes. And these processes happen to be the most finicky processes in all of alternative processes when it comes to paper’s chemical purity. I am confident that SA treated papers will perform quite well with the entire range of siderotypes.

And thanks to Loris for testing it, now I know it works flawlessly with ziatypes. I am sure he will share his thoughts on the subject as well.

I would very much like to hear your opinions on the subject, or if you see a way to optimize the procedure. And if you happen to try this acidification method to use with Kallitypes or DOP Pt/Pd I would like to hear your thoughts on the results.

P.S. I am grateful to Loris Medici for his support and guidance during this process. I could not have done it all by my own.

Best Regards,

Serdar Bilici

I heard this acid for the first time in Mike Ware’s argyrotype formula. I am no chemist by the way, but I noticed that sulfamic acid is quite a strong acid when I tossed a spoonful of it into the sink (don’t ask why). Within less than a minute I heard that it started fizzing loud, I washed it away hastily. Then I have decided to read and learn about the sulfamic acid and its uses, because I needed an acid to neutralize the buffer in papers and sulfamic acid sounded (well, it fizzed) to be capable.

It seems that sulfamic acid is used in modern descaling systems instead of hydrochloric acid, due to its less corrosive and at the same time equally strong acidic nature. It is also used in paper industry as pulp bleach. It sounded quite ideal to me because of its use in paper making and less corrosive properties.

Let me list some of the advantages of sulfamic acid

- It is a dry, non-volatile, non-hygroscopic, white crystalline substance

- It is moderately soluble in water and forms a strong acidic aqueous solution

- It is as strong as mineral acids (I have measured Ph. of 1M solution as Ph. 0)

- It is less corrosive (safer to use with stainless steel and uncoated iron materials, unlike HCl)

- Due to its non-hygroscopic nature, it can be stored in powder form indefinitely

- It is odorless! (yep it is)

- The reaction with the papers’ alkaline buffer produces only C02 gas.

- The reaction’s byproduct is highly water soluble calcium sulfamate (I cannot find solubility measurements of calcium sulfamate, but it is often referred as highly soluble in water in some articles)

I do not want to discuss in length problems with the other acids I tested for paper acidification, but suffice to say some of these problems forced me to look for an alternative. Sulfamic acid treatment causes no water insoluble solid byproduct inside the paper. There is no hazardous gas release during the process, or any respiratory irritant odor. It is cost effective and neutralizes the buffer completely with no loss of image quality.

Using sulfamic acid, I believe the treated papers become suitable for every alkaline sensitive siderotype, not just pt/pd and show no loss of dMax. I have tested various papers such as 300gsm Canson Montval, 420gsm Gvarro, 180gsm Schoellerschammer dura matt, 200gsm Fabriano Artistico Traditional White HP, 300gsm Fabriano Artistico Extra White SP, I happened to have a small piece of Hahnemühle Copplerplate warm white 300gsm and I also tested some cheap schoeller and alex drawing papers. All these papers were alkaline buffered and after treatment they all work well within expectations.

The acidification procedure is very simple and straightforward. I mixed 1M solution of Sulfamic Acid (97gr/mol), if you prefer it non-molar terms it is ca. %10 solution. 1 liter 1 molar solution of SA is approximately capable of neutralizing 50gr. of calcium carbonate. We can assume it would neutralize 20 sheet (56*76cm) paper’s buffer if we assume a sheet of paper contains 2 to 2,5gr of calcium carbonate (Thanks to Loris for providing me all these data on chemical equations and ISO9706 papers). To be safe use less number of papers, I assumed that 1lt 1M solution is capable of neutralizing 14 to 15 papers alkaline buffer safely. There is no need to emphasize the gloves and adequate ventilation, because it is always the right thing to do. Sulfamic acid is as strong as HCl, but less corrosive to metals.

I immersed the papers in SA solution for 15-20 minutes, flipping the paper 4-5 times during this wash. Of course, the length of this period will depend on the paper used. Loris noticed the reaction continues after 15minutes with 300gsm FAEW SP, and I observed the same. But with 300gsm Canson Montval, 420gsm Gvarro and 200gsm FATW HP the reaction seems to finish around 10-12 mins. Anyway, later I have decided to wash all these papers for 20minutes to be on the safe side, and I did not observe any adverse effects.

After acidification, I washed the papers (5 of them in the same tray) with tap water (chlorinated, not filtered, measured Ph. 7), for 20-25 minutes with 4-5 changes of water, and with each change of water shuffling the papers and bringing the bottom one to the top. When finished washing, I hanged the papers to dry in the bathroom.

The New Cyanotype process: As expected the sensitizer does not require additional citric acid to use with SA treated papers. The papers become chemically pure enough for new cyanotype. Adding CA to sensitizer even lowers dMax and shifts the color slightly. I have left coated paper (without CA) due to power outage for more than 12 hours and there was negligible fogging (24C %60-65RH). The amount of ilfotol depends on the paper, but I have found for Canson Montval and FATW 1drop of ilfotol per ml, for FAEW SP 2drops of ilfotol per ml work best for me.

All the samples were produced in 25C %55RH environment, printed with UVBL bulbs using non-linearized image-setter negatives. Initial wash for 1 minute in %1 sulfamic acid, then washed in tap water for 20mins.

The Argyrotype process: It worked flawlessly IMO. The sensitizer requires surfactant by nature. I have found that double the amount of ilfotol I used for new cyanotype works well for argyrotype. After determining the correct amount of ilfotol/tween I have noticed no bleeding. FAEW SP is particularly a hard surfaced paper it requires moderate humidity and quite a lot of tween or ilfotol in the sensitizer. For comparison I also included a sample printed on Masa paper, it works with new cyanotype, argyrotype and ziatype without any prior acid treatment.

All the samples were printed in 25C %55RH environment with UVBL bulbs using non-linearized image-setter negatives. Initial wash in %0.25 citric acid for 3minutes, %3 hypo for 1 min, then tap water 20mins.

Sulfamic acid treated papers work very well with the new cyanotype and argyrotype processes. And these processes happen to be the most finicky processes in all of alternative processes when it comes to paper’s chemical purity. I am confident that SA treated papers will perform quite well with the entire range of siderotypes.

And thanks to Loris for testing it, now I know it works flawlessly with ziatypes. I am sure he will share his thoughts on the subject as well.

I would very much like to hear your opinions on the subject, or if you see a way to optimize the procedure. And if you happen to try this acidification method to use with Kallitypes or DOP Pt/Pd I would like to hear your thoughts on the results.

P.S. I am grateful to Loris Medici for his support and guidance during this process. I could not have done it all by my own.

Best Regards,

Serdar Bilici

Last edited by a moderator: