Hello,

I have been practicing over the last few months with applying emulsion on aluminum plates (after coating them with a polyurethane spray) using brushes. The results were unsatisfactory due to visible brush strokes. I then started pouring the emulsion onto the plates (still pre-coating them with a polyurethane spray) and spreading the emulsion with a comb.

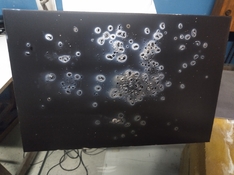

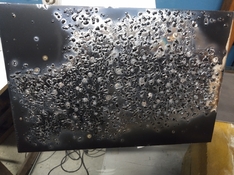

In my first attempt at pouring, I used an increadibly excessive amount of emulsion. Because I had some light issues during the drying of the emulsion, I decided to overxpose the plates to get them completely black. I then fixed and washed them. When I returned to retrieve the dry plates, I found some inexplicable defects (see the photos attached).

Could someone explain the physics/chemistry behind this?

Thanks,

Emilio

P.S. Today, I use the right amount of emulsion (a professional printer specializing in emulsion gave me the correct ratio). I tried aluminium and stainless steel (inox). I have done trials pre-coating the plates in two ways (with a polyurethane spray or by spreading highly diluted chrome alum with a soft tissue). I have some black spots on aluminium, though they are much less significant. However, nothing appears on stainless steel (which is what I finally decided to use for my project)...

I have been practicing over the last few months with applying emulsion on aluminum plates (after coating them with a polyurethane spray) using brushes. The results were unsatisfactory due to visible brush strokes. I then started pouring the emulsion onto the plates (still pre-coating them with a polyurethane spray) and spreading the emulsion with a comb.

In my first attempt at pouring, I used an increadibly excessive amount of emulsion. Because I had some light issues during the drying of the emulsion, I decided to overxpose the plates to get them completely black. I then fixed and washed them. When I returned to retrieve the dry plates, I found some inexplicable defects (see the photos attached).

Could someone explain the physics/chemistry behind this?

Thanks,

Emilio

P.S. Today, I use the right amount of emulsion (a professional printer specializing in emulsion gave me the correct ratio). I tried aluminium and stainless steel (inox). I have done trials pre-coating the plates in two ways (with a polyurethane spray or by spreading highly diluted chrome alum with a soft tissue). I have some black spots on aluminium, though they are much less significant. However, nothing appears on stainless steel (which is what I finally decided to use for my project)...

Attachments

Last edited: