- Joined

- May 7, 2008

- Messages

- 47

- Format

- 4x5 Format

I have also posted this in the Large Format Forum, so forgive me for a duplicate post.

I have been processing my 4x5 in a Jobo 3010 drum for about three months and in that time I have ruined 5 negatives, the last two today.

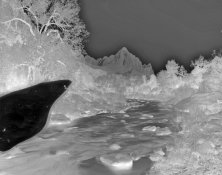

I have attached a scan of one of today's negs to see if anyone can suggest what is happening.

The first 2 or 3 times this happened, I thought that I had not gotten all the water out of the lid and some leaked down on the emulsion and sat there while the drum sat in a water bath for 10 minutes or so before processing.

However, my first batch today, the drum had been dry and unused for two weeks. I thought maybe that I had pushed the sheet down too far into the chamber where the bottom gets conical and I interupted the flow of water and chemicals. One sheet was ruined out of five in the drum.

I noted that the problem occurred in chamber #2 so I avoided that one on my next batch of three sheets and made sure I didn't push the sheets down too far. All three sheets came out fine.

Then I processed a single sheet (avoiding chamber #2 again and loading the sheet carefully) and thought I made sure the drum lid was dry. This last sheet was ruined.

All 5 sheets have a similar milky white blotch on the end of the sheet that goes into the bottom of the drum. This blotch shows up as black on the scan. You can see the exposure detail through the blotch. I looks to me as if water has sat on the film and caused the coating to go mushy or something (those are technical terms).

Can anybody guess what I'm doing wrong?

This is Fuji Acros film processed in 1:49 Rodinal at 68 degrees using a 5 minute pre-wash. Stop, fixer and washed as normal.

Thanks in advance,

Jim

I have been processing my 4x5 in a Jobo 3010 drum for about three months and in that time I have ruined 5 negatives, the last two today.

I have attached a scan of one of today's negs to see if anyone can suggest what is happening.

The first 2 or 3 times this happened, I thought that I had not gotten all the water out of the lid and some leaked down on the emulsion and sat there while the drum sat in a water bath for 10 minutes or so before processing.

However, my first batch today, the drum had been dry and unused for two weeks. I thought maybe that I had pushed the sheet down too far into the chamber where the bottom gets conical and I interupted the flow of water and chemicals. One sheet was ruined out of five in the drum.

I noted that the problem occurred in chamber #2 so I avoided that one on my next batch of three sheets and made sure I didn't push the sheets down too far. All three sheets came out fine.

Then I processed a single sheet (avoiding chamber #2 again and loading the sheet carefully) and thought I made sure the drum lid was dry. This last sheet was ruined.

All 5 sheets have a similar milky white blotch on the end of the sheet that goes into the bottom of the drum. This blotch shows up as black on the scan. You can see the exposure detail through the blotch. I looks to me as if water has sat on the film and caused the coating to go mushy or something (those are technical terms).

Can anybody guess what I'm doing wrong?

This is Fuji Acros film processed in 1:49 Rodinal at 68 degrees using a 5 minute pre-wash. Stop, fixer and washed as normal.

Thanks in advance,

Jim