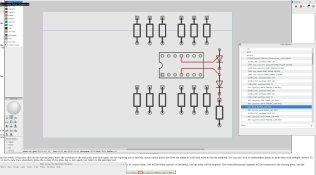

I am about to make a printed circuit board, actually it is to restore an old light meter.

I know there are modern methods and internet services probably easier and less cost,

but I thought I would like do it like 30+ years ago.

The elementary way back then was photoresist applied by brush to copper boards, then exposed under the sun

with the hand crafted artwork negative located with pins and held in a vacuum box.

- I forget all the details but it involved a trip to the (as I recall, reluctant) local photo shop for a negative.

Has anybody here done this in the darkroom, perhaps with an ordinary camera and b/w enlarger directly onto the copper?

Thanks

I know there are modern methods and internet services probably easier and less cost,

but I thought I would like do it like 30+ years ago.

The elementary way back then was photoresist applied by brush to copper boards, then exposed under the sun

with the hand crafted artwork negative located with pins and held in a vacuum box.

- I forget all the details but it involved a trip to the (as I recall, reluctant) local photo shop for a negative.

Has anybody here done this in the darkroom, perhaps with an ordinary camera and b/w enlarger directly onto the copper?

Thanks