Further on cleaning a print dryer canvas

(as noted above, I recently acquired a Premiere #110 two-sided print dryer, and want to ensure that the canvases are clean of chemicals.)

There is no obvious way to remove the canvases without completely disassembling the unit. The drying plates are flexed over a curved step integral to the plastic end pieces; the canvas cover sweeper bars are attached to springs inside the unit (which cannot be reattached without disassembly); and the canvases are attached along one long side to a bar that is held in place by the four machine screws that hold the unit together. Not confident that I could successfully reassemble the unit once I had it in pieces, I chose to wash the canvases in place.

My objective is not a canvas that appears pristine. I would like a canvas that is free of fixer or other chemicals, and so pH neutral.

I have read several reports on bulletin boards that describe various cleaning methods. If the canvas can be removed, methods used included soaking the canvas in laundry bleach, washing the canvas with dish soap, and even washing the canvas in a clothes washing machine.

I consider the challenges to be a combination of: a) an adequate washing process, b) an adequate rinsing process, c) an adequate drying process, to be accomplished without getting moisture inside the unit - on the heating element, temperature rheostat, or other wiring inside the unit. The attached photos illustrate how I approached those problems.

Materials used: pH neutral soap, cool or lukewarm water, clean mixing containers, a clean darkroom tray.

Controlling pH. I have some experience with museum conservation techniques and so ruled out using laundry bleach as it is extremely alkaline and corrosive. I was suspicious of using household dish soap because of the chemicals those may contain and because they are not typically pH neutral. A standard textile soap used by conservators is Orvus WA paste, which is available from museum conservation supply retailers and (interestingly) from animal care supply retailers. Orvus is marketed to horse stables as a shampoo for horses. In my area (northeastern United States), Tractor Supply Co. stocks it. If you look online, you may find a 'single use' package for about $4, which is plenty for this project.

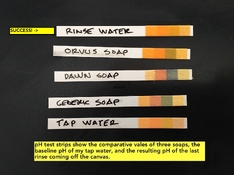

Orvus is considered to have a nearly-neutral pH. See the enclosed pH test strips and note that dish soaps tested a bit acidic. I mixed up a soapy solution of approximately 10 ml Orvus soap : 1 liter H2O. If local water quality is a concern, use distilled or filtered water. I used tap water.

Step 1: Using a clean cotton towel or cloth, apply the soap solution to each side of the canvas, until the canvas is thoroughly wetted and soap foam is visible. I started with the 'outside' and then opened the cover and repeated on the underside. Gentle scrubbing with the cloth will help loosen particulates in the fabric.

Step 2. Set the unit on end, with the canvas cover open, and allow the soap to interact with whatever particulate is present – approximately 2 or 3 minutes should be sufficient.

Step 3. Open the canvas cover over a clean tray of some sort and begin the process of rising out the soap, starting from the underside and pushing water, with a clean cloth, through to the top side. Periodically dump the dirty water that accumulates in the tray. Rinse repeatedly with fresh water, until the rinse coming off the canvas is clear. This will require multiple rinses. In my case, the first rinse water was a dark staw color. Repeat until the rinse water is visibly clear.

Step 4. After completing the rinsing process, stand the unit on end with the camvas open and allow the water to run off into the tray.

Step 5. While the canvas is still wet, close the cover so that it dries in place (avoid shrinkage).

NB: Be certain the unit is fully dry before applying electrical current!