As some may know, I was going to be building a darkroom in an old coal room in my basement. The down side it is very small 7x9. The up side is that I have 8 ceilings.

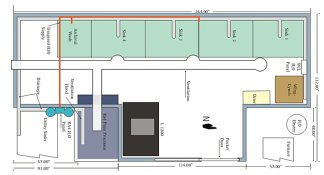

A fellow photographer and her husband, who are close friends and travel companions, have offered their basement. I have attached the preliminary plans for the darkroom and would appreciate any feedback.

The drawings are to scale and are also available as a coreldraw, eps or freehand file if anyone wishes to edit them directly.

Some notes on the drawings:

A fellow photographer and her husband, who are close friends and travel companions, have offered their basement. I have attached the preliminary plans for the darkroom and would appreciate any feedback.

The drawings are to scale and are also available as a coreldraw, eps or freehand file if anyone wishes to edit them directly.

Some notes on the drawings:

- The darkroom will sit against the west, north and south walls of the basement.

- The sinks are large enough to handle 30x40 prints.

- The enlarger (durst L1200) will need to be oriented north/south because the top will be situated between floor joices.

- The ceilings and walls will be all dry walled (sheetrock) the walls will have aluminum studs.

- Ventilation will be placed over the sinks and a hood over the RA4 processor. Recommendations on ventilation are enthusiastically requested.