bernard_L

Member

- Joined

- Feb 17, 2008

- Messages

- 1,959

- Format

- Multi Format

Olympus Pen EES-2 rescue and repair

Context. Bought a Pen EE -2 at a camera fair, cheap. Shot two dozen frames, cityscapes. Nice little camera, carefree, forget adjustments and just think about subject and composition. But was frustrated with no focus: depth of field can't be that large, so sharpness is a lottery for near- and mid-range subjects. GAS-sing for a Pen EES-2 with focus adjust; no way I would pay the going prices on the auction site. So I bought one "for parts" camera, stated as "shutter inoperative"; should be easy: dis-assembly, naphta, wipe, re-assemble.

The camera I received had been tampered by an idiot; in French we call them blaireau (badger). The "tower" parts of the lens cylinder was mounted with random orientations, tilting sideways like the tower of Pisa; screws were missing; and worse of all the blaireau had punched a hole through one shutter blade. The protruding edges of the hole were blocking the motion of the blade; the shutter cycle could not complete.

I give below some information on my repair. I benefitted from valuable and detailed information given by Mikeno62 on his youtube channel:

especially parts 1 and 4. My memo is not a detailed step-by-step procedure but focuses on key points.

Separate lens assembly from body

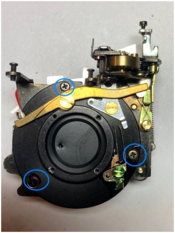

The lens assemby is held on the body primarily by the four screws around the shutter, behind the film gate (see pic above), but also by the two plates in front, below the leatherette. One also needs to remove the top and bottom body covers. My experience was: (a) remove the four screws at the back; lens is loose but not free; (b) remove the two front plates; (c) separate the lens from body (except for the wires).

Dismantling of lens "tower"

This means the pile of rings for ASA/ISO, distance, AUTO/f-stop. First remove the front element; see the video by Mikeno62 starting at 3'03" to preserve the infinity setting. In my case, given the sad state of that camera, there was most likely nothing to preserve. Remove the photocell assembly (see below about wiring). Then proceed. Caution: two of the black rings have a small bearing ball for click stops; they are normally held in place by a little grease. Clean the rings from accumulated dust/crud.

About wiring.

You don't want to do repair work with all the wiring attached. And in my case, the light meter circuit wires had he insulator cracked, so I replaced them; and the sync wiring as well for good measure; the latter needs a thick enough insulator to withstand the 300V (or so) voltage of old flash units. If you do not need to replace the light meter wires, I would advise to leave alone the solder joints on the Selenium photocell: the solderable metal there is thin and if it's gone, all is lost. Also leave alone the solder joints on the galvanometer. My recommendation is to cut the wires next to the viewfinder then pull the wires and set the photocell aside; make a note of which hole the wires go through; when re-assembling protect the solder junction with shrink tube. There is a small resistor in series in the photocell circuit; I measured 4.1kΩ but the value might be different, chosen on the assembly line to mitigate photocell tolerance.

Besides the photocell, other solder points are delicate: the sync contact on the shutter and the sync contact in the hot shoe, because of nearby thermoplastic parts. I used a small 12W iron, but in retrospect it would have been better to use a bigger iron to minimize the soldering time.

Repair of shutter blade

See below a picture of the lens+shutter assembly. The indicated three screws hold the shutter blade support plate. After removing the screws, hold the two parts together and flip over, then lift the assembly, revealing the shutter blade plate. The blades are 50µm (2mil) thick.

With the damaged blade on a flat surface, I sanded the burrs on the edge of the hole with P600 (EU grade) grit sandpaper. Then I glued a patch of 15µM (0.6 mil) copper-beryllium, with cyanoacrylate, using polyethylene sheets (cut from a Ziploc bag) to press the patch while the glue was setting. There is still a small hump, but the height of the blade housing is sufficient to accommodate it. The important point is that the patch extends out beyond the edge of the opening so it never has to go over a step when the blades open.

Attachments

Last edited by a moderator: