bobfowler

Subscriber

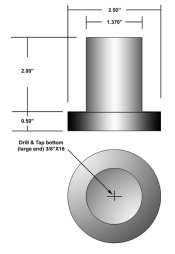

I just got a Majestic head to use with my Calumet Green Monster. I have a Davis & Sanford Model C tripod which the head fits just fine, but I'd like to be able to use it on my Bogen 3036 as well. There are a couple of adapters out there (B&H will special order them) that will allow the slip on head to be used on my 3036, but I'm not crazy about the way they are made.

While I can handle woodwork and most sheet metal work, this one is beyond my current tool set. What I'd like is a single piece of steel machined as to the picture I've attached to this posting.

If you can help. please PM me with an estimate of the cost.

Thanks!

While I can handle woodwork and most sheet metal work, this one is beyond my current tool set. What I'd like is a single piece of steel machined as to the picture I've attached to this posting.

If you can help. please PM me with an estimate of the cost.

Thanks!