Huss

Member

Got a shoot on Friday. Was testing my gear to make sure all a-ok before the main event. Specifcally I was testing my slave flash syncs - using a SB 700 as a slave, triggering it with an SB400 on my Nikon F6.

All was working great until I tried to remove the 400 and test more with an SB 500. The 400 would not release. The locking pin mechanism had broken!

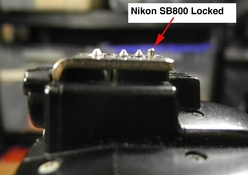

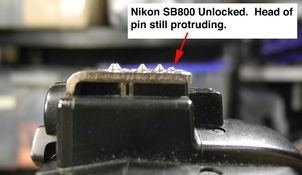

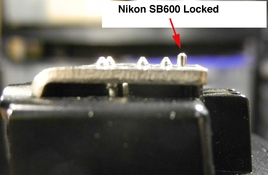

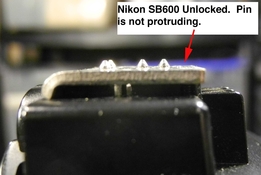

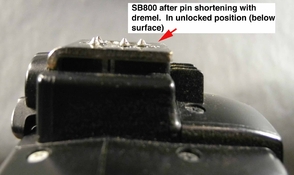

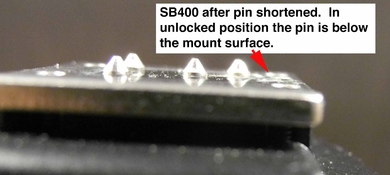

Took it to my local repair dood - a Nikon trained tech - who used as many expletives as I did when shown my dilemma. He said that he's seen so many Nikon and Canon speedlights that have failed like this. The pin is spring loaded so when/if the mechanism fails - which it apparently often does, the only way to remove it is to get physical. He has to cut my SB400 off the camera to get into the locking mechanism to release it!

Remember the good old days when your strobe had the spinning wheel to lock it down? I do.

Going forward I will never use the lock lever on these Nikon Speedlights. Stoopid Nikon.

Wheel vs lever - the Sunpak was a freebie that works fine on any camera as a standard flash:

All was working great until I tried to remove the 400 and test more with an SB 500. The 400 would not release. The locking pin mechanism had broken!

Took it to my local repair dood - a Nikon trained tech - who used as many expletives as I did when shown my dilemma. He said that he's seen so many Nikon and Canon speedlights that have failed like this. The pin is spring loaded so when/if the mechanism fails - which it apparently often does, the only way to remove it is to get physical. He has to cut my SB400 off the camera to get into the locking mechanism to release it!

Remember the good old days when your strobe had the spinning wheel to lock it down? I do.

Going forward I will never use the lock lever on these Nikon Speedlights. Stoopid Nikon.

Wheel vs lever - the Sunpak was a freebie that works fine on any camera as a standard flash: