Klainmeister

Member

Hi All,

As you know, we've been working with fumed silica quite a bit at Bostick & Sullivan recently. We've experimented with different coating methods, but we find that the traditional roll on method is the most efficient/easy, but has the risk of streaking. A good rule of thumb is to use a foam roller in a tray, get it soaked up and covered with dry silica, and use that on the paper for an even coat. Instead of pouring some on the paper directly, the amount that the roller holds seems to be just right.

Another method is to make a solution in water and soak the paper in it. This greatly reduces the chance of streaking, but comes at the cost of extra time and the chance of making the paper warped/wavy for the next process. If you were doing a large amount of big prints, this might be a good idea to do the day prior to a large print session. We had success with PT prints 20"+.

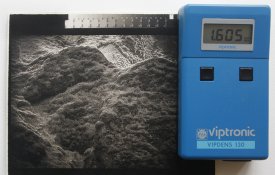

Proof in point of what this does for your PT/PD prints (Cyano and Vandyke equally respond), here is a shot of two prints I did Saturday. The one on the left is straight Palladium with no Fumed Silica, the one on the right is exactly the same negative, same paper, same formula, same exposure, but with silica. Oddly, I found that the silica required less PT/PD solution (by one whole dropper full), mainly because it didn't soak into the paper as rapidly and was easier to get a full coating. Example, this 14x18" print took 3 full droppers of both Palladium and Ferric Oxalate to do with the silica coated paper, without it took 4 (and probably could have used 4.5).

On a side note, we're going to start posting information and more photos to a Facebook page, blog, and begin How-To videos on all the processes offered via a youtube channel. Stay tuned!

As you know, we've been working with fumed silica quite a bit at Bostick & Sullivan recently. We've experimented with different coating methods, but we find that the traditional roll on method is the most efficient/easy, but has the risk of streaking. A good rule of thumb is to use a foam roller in a tray, get it soaked up and covered with dry silica, and use that on the paper for an even coat. Instead of pouring some on the paper directly, the amount that the roller holds seems to be just right.

Another method is to make a solution in water and soak the paper in it. This greatly reduces the chance of streaking, but comes at the cost of extra time and the chance of making the paper warped/wavy for the next process. If you were doing a large amount of big prints, this might be a good idea to do the day prior to a large print session. We had success with PT prints 20"+.

Proof in point of what this does for your PT/PD prints (Cyano and Vandyke equally respond), here is a shot of two prints I did Saturday. The one on the left is straight Palladium with no Fumed Silica, the one on the right is exactly the same negative, same paper, same formula, same exposure, but with silica. Oddly, I found that the silica required less PT/PD solution (by one whole dropper full), mainly because it didn't soak into the paper as rapidly and was easier to get a full coating. Example, this 14x18" print took 3 full droppers of both Palladium and Ferric Oxalate to do with the silica coated paper, without it took 4 (and probably could have used 4.5).

On a side note, we're going to start posting information and more photos to a Facebook page, blog, and begin How-To videos on all the processes offered via a youtube channel. Stay tuned!