Hello people,

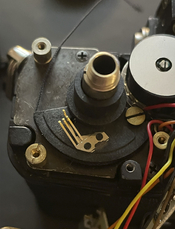

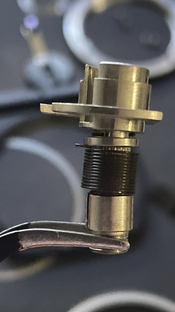

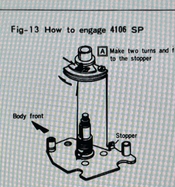

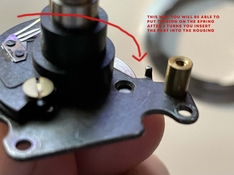

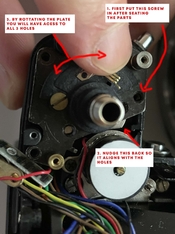

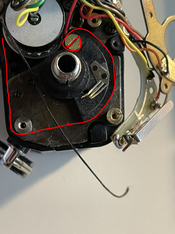

I bought a Minolta XE-1 was super hyped but up on further inspection the aperture pulley was disconnected and a part of the rewind base plate was bent. I'm not sure if the rod who holds the film canister is bent too. This most likely contributed to the aperture "half wheel" looking part not moving correctly anymore. The camera itself is fine in any other department shutter is smooth and the light meter works and the overall condition is nice. My question since the xe-5 and xe-1 are similar would I be able to get that spare part from an XE-5 and replace it?

thanks

I bought a Minolta XE-1 was super hyped but up on further inspection the aperture pulley was disconnected and a part of the rewind base plate was bent. I'm not sure if the rod who holds the film canister is bent too. This most likely contributed to the aperture "half wheel" looking part not moving correctly anymore. The camera itself is fine in any other department shutter is smooth and the light meter works and the overall condition is nice. My question since the xe-5 and xe-1 are similar would I be able to get that spare part from an XE-5 and replace it?

thanks