Andreas Thaler

Member

Another broken X-700:

In post

„Minolta X-700: Electronics fault > spare parts box“

www.photrio.com

www.photrio.com

I suspect the built-in electrolytic capacitors (E) and tantalum capacitors (T) are responsible for problems of this kind.

The X-700 has eight of these (numbering according to the service manual):

Where are the locations of these capacitors?

An abandoned X-700 serves for the section.

(The circuit is no longer 100 percent original as the previous owner and I have already worked on it, but that doesn't matter for this purpose.)

With the top cover removed - top view of the flexible circuit board.

The ring with the contacts for ASA and override adjustment.

Cable connections …

... unsoldered

After loosening two screws on the top, the board can now be bent up (carefully).

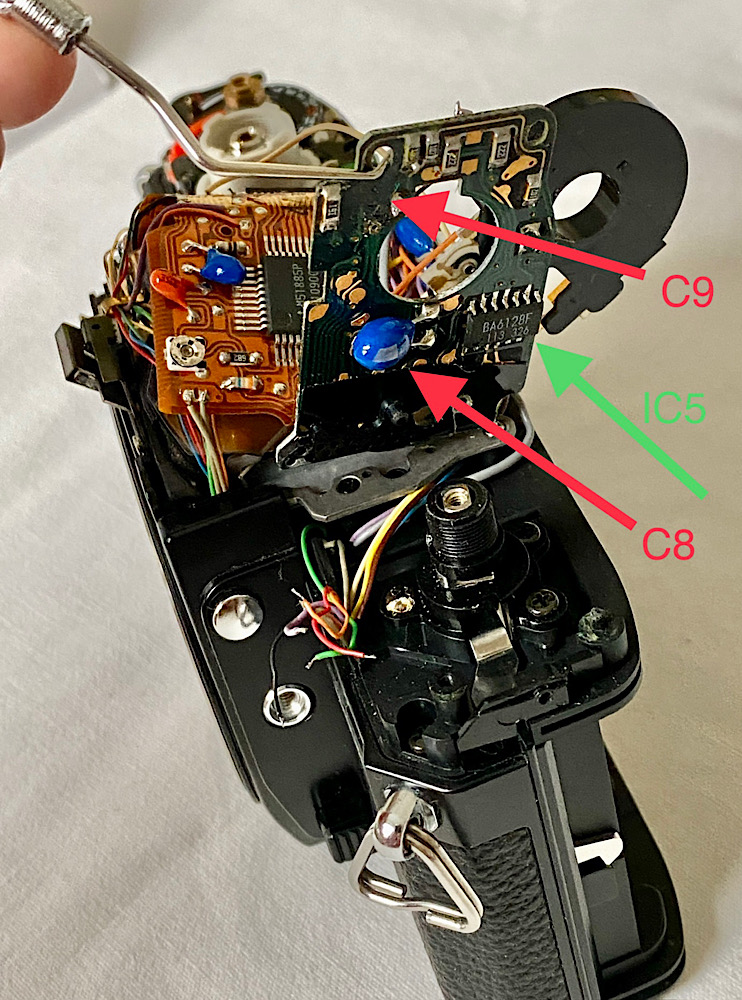

IC5, C8 and C9 (latter already removed here) are therefore accessible.

The other positions.

The circuit board around the eyepiece with cable connections and measuring cell.

The board is folded up - IC3 and IC4 become accessible. All connected cables have to be unsoldered before.

The version number of the board.

The oscillating quartz for digital clocking.

C10 in the camera base.

Interim conclusion

- LEDs in the viewfinder light up when you press the shutter button

- Shutter does not fire when the shutter button is pressed, LEDs go out

- LEDs can then be „tapped“ again

- OFF/ON main switch is not required for this

In post

„Minolta X-700: Electronics fault > spare parts box“

Troubleshooting electronic SLRs: There is little you can do, but do it

I wonder what options there are to find and resolve errors in a highly integrated electronic camera circuit. For example, the Minolta X-700 five ICs, several discrete electronic components and electromechanical parts. Under the hood of the Minolta X-700 It is of course possible to go in...

I suspect the built-in electrolytic capacitors (E) and tantalum capacitors (T) are responsible for problems of this kind.

The X-700 has eight of these (numbering according to the service manual):

- C1 (T)

- C2 (T)

- C3 (T)

- C4 (T)

- C5 (T)

- C8 (T)

- C9 (E)

- C10 (E)

Where are the locations of these capacitors?

An abandoned X-700 serves for the section.

(The circuit is no longer 100 percent original as the previous owner and I have already worked on it, but that doesn't matter for this purpose.)

With the top cover removed - top view of the flexible circuit board.

The ring with the contacts for ASA and override adjustment.

Cable connections …

... unsoldered

After loosening two screws on the top, the board can now be bent up (carefully).

IC5, C8 and C9 (latter already removed here) are therefore accessible.

The other positions.

The circuit board around the eyepiece with cable connections and measuring cell.

The board is folded up - IC3 and IC4 become accessible. All connected cables have to be unsoldered before.

The version number of the board.

The oscillating quartz for digital clocking.

C10 in the camera base.

Interim conclusion

- If you are prepared to undertake the extensive task of unsoldering/soldering on the cables, all of the capacitors mentioned are very easy to reach and replace.

- A systematic approach and image documentation of where which cable connects are helpful.

- The service manual also provides information about the connections in a diagram.

- Likewise, all five ICs would be very easily accessible for possible replacement. However, the number of pins (64) and their size pose soldering challenges for ICs 1 to 4.

- Judging by the year the camera was built and the shine of the solder joints, the soldering was done with lead-based solder. It is therefore advisable to also work with such solder in order to avoid any problems when mixing two types of solder (different melting points).

Last edited: