Photo Engineer

Subscriber

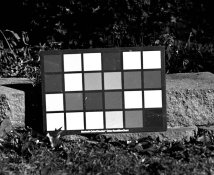

Here is a sample of a glass plate made at a recent workshop.

It is Orthochromatic and has an ISO of 40 - 60. It was exposed at 1/100th f8.

The process was 9 minutes in D76, stop, fix in Kodak RLF + hardener.

The image represents an area of about 3x4 inches of the entire 4x5 plate due to edge defects and frilling. The edge of one such defect can be seen at the upper right of this picture.

There appears to be less flare than would be expected due to the absence of an absorber dye or AH layer.

This is an SRAD (Single Run Ammonia Digest) with Erythrosine used as the green sensitizing dye. It was made using Phthalated Gelatin (PA) and was ISO washed with an acid base cycle. It was chemically sensitized with sulfur using Sodium Thiosulfate. If I were to use gold, the speed would be about one stop faster, as a guess OTOMH.

The Dmin was clean, and the contrast was good. This plate was coated at about 500 - 700 mg/foot sqare of silver with about 1000 mg of gelatin including the PA gelatin. Coating was carried out with a plate coating doctor blade. This plate was kept for 4 days to complete the hardening cycle as far as possible. I have 2 more plates awaiting testing.

In addition, there were coatings on Estar support at 5 mil (about 300 mg / ft square of silver and about 750 mg of gelatin / ft square. Paper coatings were also made and had the expected speed of about 100 - 200 ISO due to back reflection. These paper coatings made nice paper negatives.

PE

It is Orthochromatic and has an ISO of 40 - 60. It was exposed at 1/100th f8.

The process was 9 minutes in D76, stop, fix in Kodak RLF + hardener.

The image represents an area of about 3x4 inches of the entire 4x5 plate due to edge defects and frilling. The edge of one such defect can be seen at the upper right of this picture.

There appears to be less flare than would be expected due to the absence of an absorber dye or AH layer.

This is an SRAD (Single Run Ammonia Digest) with Erythrosine used as the green sensitizing dye. It was made using Phthalated Gelatin (PA) and was ISO washed with an acid base cycle. It was chemically sensitized with sulfur using Sodium Thiosulfate. If I were to use gold, the speed would be about one stop faster, as a guess OTOMH.

The Dmin was clean, and the contrast was good. This plate was coated at about 500 - 700 mg/foot sqare of silver with about 1000 mg of gelatin including the PA gelatin. Coating was carried out with a plate coating doctor blade. This plate was kept for 4 days to complete the hardening cycle as far as possible. I have 2 more plates awaiting testing.

In addition, there were coatings on Estar support at 5 mil (about 300 mg / ft square of silver and about 750 mg of gelatin / ft square. Paper coatings were also made and had the expected speed of about 100 - 200 ISO due to back reflection. These paper coatings made nice paper negatives.

PE