As the title says, I’m designing a film slitter. The capacity will be 14”x1000’, or way more than I’ll ever reasonably need. But I’m building it to try and make it as futureproof as I can.

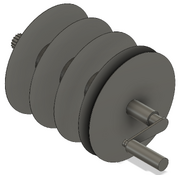

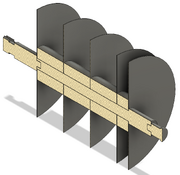

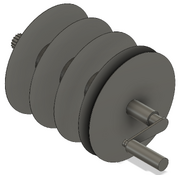

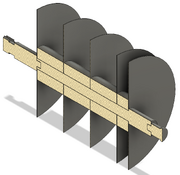

This is the takeup assembly. The shaft will fit cores with a 1” ID and keyway, like most 2-3” OD cine cores. To allow for removal of the film, the shaft is 3 parts. The flanges and cores just slide on and off. The handle has a free spinning grip. Shown here is a setup for 240mm to 70mm.

This is the takeup assembly. The shaft will fit cores with a 1” ID and keyway, like most 2-3” OD cine cores. To allow for removal of the film, the shaft is 3 parts. The flanges and cores just slide on and off. The handle has a free spinning grip. Shown here is a setup for 240mm to 70mm.

Looks like a nice design. I worked around huge extrusion equipment for making large sheets of ABS for appliances. As the molten plastic was pulled from the die lips, after it would stabilize going forward, the production folks would lower knives into the still soft plastic, worked slick. IIRC the sheet was about 65-70 inches wide, once cool enough it would be sheared to proper length with a quick chop of a huge blade. It was quite rigid when chopped.

Looks like a nice design. I worked around huge extrusion equipment for making large sheets of ABS for appliances. As the molten plastic was pulled from the die lips, after it would stabilize going forward, the production folks would lower knives into the still soft plastic, worked slick. IIRC the sheet was about 65-70 inches wide, once cool enough it would be sheared to proper length with a quick chop of a huge blade. It was quite rigid when chopped.