Also, being new to the forums, I see references to books mentioned on this forum by the author(s) last name(s), but no titles. I would guess this is because these books are well known to the list members. Is there a post on this forum or some other source which gives details of the book titles and their respective authors?

If it's my post, I can supply those info. If you are seriously interested, feel free to write me but please include your email address.

Also, check this out:

Dead Link Removed

I wanted to know if anyone knows how (without venturing too far over the "proprietary information" line) Kodak's Tech Pan emulsion construction / formulation / etc., differs from other B&W films, and if there is any patent discussing the Tech Pan emulsion.

I still have quite a bit of Tech Pan (they are for sale too!) so I could analyze the emulsion for some basic parameters...

The Tech Pan is most different from pictorial negative films in (1) extended red sensitivity, (2) inherently higher emulsion contrast and much narrower exposure latitude, (3) finer crystal size.

The extended red sensitivity is due to a different sensitizing dye. The higher emulsion contrast is due to more uniform crystal sizes in very narrow size distribution (many negative emulsions use multiple emulsions of different grain sizes to increase latitude and decrease contrast).

Tech Pan was introduced in late 1970s. Considering the emulsion making technology of that time, and the required specification for Tech Pan, I think the most likely choice would be cubic AgBrI crystals of edge size about 0.1 to 0.2 micron. Well, the right answer can be found easily by dissolving a bit of emulsion off the film and looking at the crystals under electron microscope.

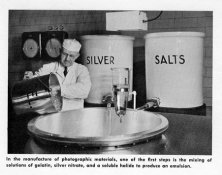

This type of emulsion was most commonly made with a conventional double jet system. Most likely with a reaction vessel with a premixing chamber, a pair of electrodes to monitor pAg, pH, and temperature, with automatic feedback control system. The flow control of both jets (silver jet and halide jet) is very critical to maintain a certain target pAg value, or the emulsion won't be as high contrast. And the target pAg ideal for high contrast emulsions will most naturally make cubic AgBr crystals, unless the crystal habit is chemically modified, but at that time this technology wasn't developed yet.

In order to make a high resolution emulsion, you must design the crystal size very carefully. Emulsions with crystal sizes in 0.2 to 0.5 micron range is not very easy to use for very high resolution applications because of large scattering of light caused by the crystals themselves. Tabular grain emulsions have a definite advantage here.

Incidentally, many paper emulsions are in the size of 0.2 to 0.5 microns. They are also coated on reflective paper. So they have terrible resolution although the emulsion is very slow compared to the negative emulsions.

Also, Technical Pan is not a lith film, as users of both types of film can tell. Lith films are usually AgClBr emulsions, possibly with a very small amount of iodide. Bromide emulsions don't develop very well in classic lith developers that was in active use at the time of Tech Pan's introduction to the market.