Photo Engineer

Subscriber

Ok, this is going to be bare bones with no frills and will only address simple multilayers, not all of the consituents..

In a reversal film, it contains up to 3 red and blue sensitive emulsions which are blended. The highest speed emulsion is usually one stop faster plus a small amount than the desired ISO speed and the lowest speed emulsion is usually one stop slower less a little bit. The middle emulsion is at the ISO speed plus a little bit. This tiny amount (up to 1/2 stop excess) will be explained below.

These 3 emulsions are foggy and rather high contrast so that you get an aim color contrast of about 1.8 and the fog helps clear out the minimum density by developing all grains possible in the dmax area through development to completion.

These emulsions are blended with a coupler or a mix of couplers and the amount used must attain a density of at least 3.0 when fully developed. The couplers may be dissolved in gelatin and then precipitated (Fischer-Agfa method) or they may be dissolved in oil and dispersed using a colloid mill (Kodak method). In the latter case, dye stabilzers may also be added.

Now, this is the red layer. The green is the same and the blue is the same, but under the blue layer, a yellow dye or silver layer is coated to protect the green and red layers from being exposed to blue light. Inter layers are added to protect each layer from contaminating the other layers with diffusing oxidized color developer.

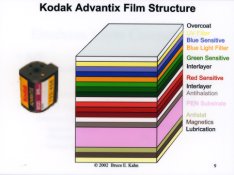

The layer order is Overcoat/Blue-yellow dye forming/yellow dye layer/Green-magenta dye forming/interlayer/Red-cyan dye forming/AH/support - Estar or acetate/antistat

Since an emulsion cannot be made that is invariant in speed, the 'little bit extra speed' above is used in 2 ways. First, dyes are added to prevent internal light reflection and reduce turbidity effects, and secondy they are added to balance the speeds of the layers to improve sharpness and speed. These are called acutance or trimmer dyes.

End of reversal films.

----------------------------

Now for negative films.

Consider them as being the same as above but with the following changes.

First, the emulsions are low fog and low contrast. The aim is about 0.6. Second, the coupler is coated much lower than the silver but still enough to get a dmax of 3.0. This is to improve image quality. Silver to coupler ratio is high, so that the system is what is called 'coupler starved'

The red layer contains a cyan coupler, an orange masking coupler, and a DIAR or DIR coupler to enhance sharpness and color effects. They do not help much in reversal films since the development goes to completion.

The magenta layer contains a magenta coupler, a yellow masking coupler and a DIAR or DIR coupler.

The yellow layer contains a yellow coupler and a DIAR or DIR coupler.

The layer order may be as follows:

Overcoat/Blue layer/yellow dye layer/Fast magenta/medium magenta/slow magenta/interlayer/fast cyan/medium cyan/slow cyan/AH/Support/Antistat.

Actual color films may contain up to 14 layers and can be coated in one pass.

The DIR and DIAR couplers are imaging couplers that work by Developer Inhibitor Release, in which an inhibitor is released during development which improves image structure. The layer order is changed for this same reason, but acutance dyes and trimmer dyes are still used.

If you use a prewet, you see these latter dyes wash out of ALL films (B&W and color both) during the dump of the prewet.

Hope this helps some of you understand color film better.

Kodachrome is a multilayer B&W film sensitive to all light, and the dyes form in the film in 3 reversal development steps. It is much thinner than the above films due to the lack of couplers, but when the image dyes form, the emulsion bulges around the dye clouds and forms the well known Kodachrome relief image. This helps enhance Kodachrome's sharpness.

PE

In a reversal film, it contains up to 3 red and blue sensitive emulsions which are blended. The highest speed emulsion is usually one stop faster plus a small amount than the desired ISO speed and the lowest speed emulsion is usually one stop slower less a little bit. The middle emulsion is at the ISO speed plus a little bit. This tiny amount (up to 1/2 stop excess) will be explained below.

These 3 emulsions are foggy and rather high contrast so that you get an aim color contrast of about 1.8 and the fog helps clear out the minimum density by developing all grains possible in the dmax area through development to completion.

These emulsions are blended with a coupler or a mix of couplers and the amount used must attain a density of at least 3.0 when fully developed. The couplers may be dissolved in gelatin and then precipitated (Fischer-Agfa method) or they may be dissolved in oil and dispersed using a colloid mill (Kodak method). In the latter case, dye stabilzers may also be added.

Now, this is the red layer. The green is the same and the blue is the same, but under the blue layer, a yellow dye or silver layer is coated to protect the green and red layers from being exposed to blue light. Inter layers are added to protect each layer from contaminating the other layers with diffusing oxidized color developer.

The layer order is Overcoat/Blue-yellow dye forming/yellow dye layer/Green-magenta dye forming/interlayer/Red-cyan dye forming/AH/support - Estar or acetate/antistat

Since an emulsion cannot be made that is invariant in speed, the 'little bit extra speed' above is used in 2 ways. First, dyes are added to prevent internal light reflection and reduce turbidity effects, and secondy they are added to balance the speeds of the layers to improve sharpness and speed. These are called acutance or trimmer dyes.

End of reversal films.

----------------------------

Now for negative films.

Consider them as being the same as above but with the following changes.

First, the emulsions are low fog and low contrast. The aim is about 0.6. Second, the coupler is coated much lower than the silver but still enough to get a dmax of 3.0. This is to improve image quality. Silver to coupler ratio is high, so that the system is what is called 'coupler starved'

The red layer contains a cyan coupler, an orange masking coupler, and a DIAR or DIR coupler to enhance sharpness and color effects. They do not help much in reversal films since the development goes to completion.

The magenta layer contains a magenta coupler, a yellow masking coupler and a DIAR or DIR coupler.

The yellow layer contains a yellow coupler and a DIAR or DIR coupler.

The layer order may be as follows:

Overcoat/Blue layer/yellow dye layer/Fast magenta/medium magenta/slow magenta/interlayer/fast cyan/medium cyan/slow cyan/AH/Support/Antistat.

Actual color films may contain up to 14 layers and can be coated in one pass.

The DIR and DIAR couplers are imaging couplers that work by Developer Inhibitor Release, in which an inhibitor is released during development which improves image structure. The layer order is changed for this same reason, but acutance dyes and trimmer dyes are still used.

If you use a prewet, you see these latter dyes wash out of ALL films (B&W and color both) during the dump of the prewet.

Hope this helps some of you understand color film better.

Kodachrome is a multilayer B&W film sensitive to all light, and the dyes form in the film in 3 reversal development steps. It is much thinner than the above films due to the lack of couplers, but when the image dyes form, the emulsion bulges around the dye clouds and forms the well known Kodachrome relief image. This helps enhance Kodachrome's sharpness.

PE