perkeleellinen

Subscriber

Hello all,

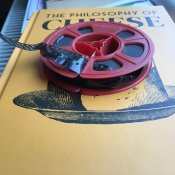

I have been given my late uncle's standard 8 home movies - around 20 reels from the 1960s, some stored in an appalling state with the film folded in on itself on the reel. The better ones I'm having trouble projecting and I keep chewing up leader tape. I'm worried I'll destroy these movies if I keep persevering.

These films are so strange and I just can't get them to thread into the projector. I've tried two different machines now and both a chewing up the leaders. I suspect user error, am I threading backwards? If I am, why is there a leader on the end?

25 years of projecting Super 8 and I've never had an issue as weird as this!

Thanks!

I have been given my late uncle's standard 8 home movies - around 20 reels from the 1960s, some stored in an appalling state with the film folded in on itself on the reel. The better ones I'm having trouble projecting and I keep chewing up leader tape. I'm worried I'll destroy these movies if I keep persevering.

- If a movie projects backwards, upside down and inverted does that mean the reel was not rewound some time in the past?

- Should standard 8 feed into the projector with the sprocket holes toward me or away from me?

- Did standard 8 film get developed with leaders on both ends?

These films are so strange and I just can't get them to thread into the projector. I've tried two different machines now and both a chewing up the leaders. I suspect user error, am I threading backwards? If I am, why is there a leader on the end?

25 years of projecting Super 8 and I've never had an issue as weird as this!

Thanks!

)

)