Atomic_03

Subscriber

Hello everybody!

This is my first post and is in regards to the operation of the machine titled above.

I would assume the operation of and getting it started is similar to that of a cp-31?

Other than this model being older, is there really any major difference?

If anybody has any experience with this and could help, it would be greatly appreciated!

I’m currently not making enough prints to use this, but will soon be wanting to be more efficient, so getting this up and running safely would be amazing!

Thank you!

This is my first post and is in regards to the operation of the machine titled above.

I would assume the operation of and getting it started is similar to that of a cp-31?

Other than this model being older, is there really any major difference?

If anybody has any experience with this and could help, it would be greatly appreciated!

I’m currently not making enough prints to use this, but will soon be wanting to be more efficient, so getting this up and running safely would be amazing!

Thank you!

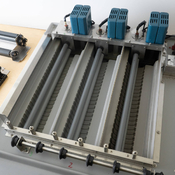

Attachments

-

IMG_2615.jpeg91.3 KB · Views: 31

IMG_2615.jpeg91.3 KB · Views: 31 -

IMG_2616.jpeg75.8 KB · Views: 27

IMG_2616.jpeg75.8 KB · Views: 27 -

IMG_2617.jpeg73.7 KB · Views: 25

IMG_2617.jpeg73.7 KB · Views: 25 -

IMG_2618.jpeg57.9 KB · Views: 27

IMG_2618.jpeg57.9 KB · Views: 27 -

IMG_2619.jpeg146.7 KB · Views: 25

IMG_2619.jpeg146.7 KB · Views: 25 -

IMG_2620.jpeg146.9 KB · Views: 24

IMG_2620.jpeg146.9 KB · Views: 24 -

IMG_2621.jpeg156.6 KB · Views: 26

IMG_2621.jpeg156.6 KB · Views: 26 -

IMG_2622.jpeg156.9 KB · Views: 25

IMG_2622.jpeg156.9 KB · Views: 25 -

IMG_2623.jpeg166.1 KB · Views: 31

IMG_2623.jpeg166.1 KB · Views: 31