I can see how people can get both frustrated and addicted to lith printing. I tried a couple of images and I'd be well on my way to addiction except for one problem.

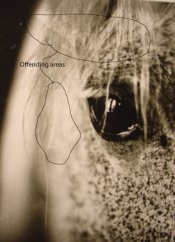

I'm using Forte polywarmtone and finding that that I have lighter colored streaks with some fairly well defined edges. It almost looks like something was laid down on the paper for about half the exposure. A scan is attached. I've used this box of paper for regular printing and it was fine. Earlier in the session I was printing another negative with Forte neutral paper (and fresher developer) and I did not have the problem. My first thought is that it is the paper, but it could also be something about my process. I was very careful not to touch anything to the paper surface. It would be a shame if it was the paper since I like the results otherwise. Any thoughts?

Thanks -- Mark

I'm using Forte polywarmtone and finding that that I have lighter colored streaks with some fairly well defined edges. It almost looks like something was laid down on the paper for about half the exposure. A scan is attached. I've used this box of paper for regular printing and it was fine. Earlier in the session I was printing another negative with Forte neutral paper (and fresher developer) and I did not have the problem. My first thought is that it is the paper, but it could also be something about my process. I was very careful not to touch anything to the paper surface. It would be a shame if it was the paper since I like the results otherwise. Any thoughts?

Thanks -- Mark