Hi,

I made my first print with ferrotyping/glazing process and got a problem. There is some kind of pitting all over the print emulsion. Does anyone here know what the problem is?

I use Ilford MG FB glossy paper.

Here is my process:

Developing and washing print according to Ilford archival method. (Ilford Rapid fixer used.)

Rinsed the print in destilled water with Adox Adoflo dilution 1:200.

Cleaned the chrome plate(brand new, never used in perfect condition) with soap and a tap water rinse. Finally rinsed the plate in destilled water with Adox Adoflo dilution 1:200 as I did with the print. Both print and chromed plate are wet when combined, emulsion side on the plate, and I used a roller to press out the water between the print and chrome plate.

Placed the print and plate in the dryer(double canvas-type dryer) and let it dry for approx 1 hour with heat on, then I let the print stay in the dryer for another 12h with heater off.

The print was easily separated from the chrome plate, pops off by itself, when dry and I can not see any pieces of gelatin sticking on the chrome plate. Plate clean as new.

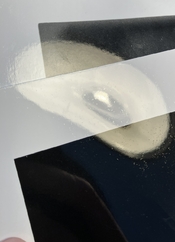

You can see example of the pitting (in the glare ande reflection of the lamp) in the attached photo.

Best regards

/Christian

I made my first print with ferrotyping/glazing process and got a problem. There is some kind of pitting all over the print emulsion. Does anyone here know what the problem is?

I use Ilford MG FB glossy paper.

Here is my process:

Developing and washing print according to Ilford archival method. (Ilford Rapid fixer used.)

Rinsed the print in destilled water with Adox Adoflo dilution 1:200.

Cleaned the chrome plate(brand new, never used in perfect condition) with soap and a tap water rinse. Finally rinsed the plate in destilled water with Adox Adoflo dilution 1:200 as I did with the print. Both print and chromed plate are wet when combined, emulsion side on the plate, and I used a roller to press out the water between the print and chrome plate.

Placed the print and plate in the dryer(double canvas-type dryer) and let it dry for approx 1 hour with heat on, then I let the print stay in the dryer for another 12h with heater off.

The print was easily separated from the chrome plate, pops off by itself, when dry and I can not see any pieces of gelatin sticking on the chrome plate. Plate clean as new.

You can see example of the pitting (in the glare ande reflection of the lamp) in the attached photo.

Best regards

/Christian

). In the US there was Pakosol and Kodak Print Flattening solution used for glazing.

). In the US there was Pakosol and Kodak Print Flattening solution used for glazing.