pavelkim

Member

Hello everyone,

I've bought Durst L900 several years ago, but it went with a small defect in the lifting mechanism.

There are a gear in the head and a gear plane (is that a correct term?) on the back of the column. They both got broken teeth.

Decided lately to order duplicates for both parts and put the enlarger back in order.

Well... I can't disassemble the head much enough to take the gear off (;

I've read service manual in French, but didn't find the answer.

Can anyone advise?

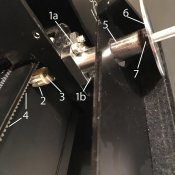

Pictures:

Details so far:

1a and 1b — stuck.

7 — no idea what this is, but it doesn't look like a screw.

6 — sits tight, can't take it off.

3 — apparently not a screw.

I've bought Durst L900 several years ago, but it went with a small defect in the lifting mechanism.

There are a gear in the head and a gear plane (is that a correct term?) on the back of the column. They both got broken teeth.

Decided lately to order duplicates for both parts and put the enlarger back in order.

Well... I can't disassemble the head much enough to take the gear off (;

I've read service manual in French, but didn't find the answer.

Can anyone advise?

Pictures:

Details so far:

1a and 1b — stuck.

7 — no idea what this is, but it doesn't look like a screw.

6 — sits tight, can't take it off.

3 — apparently not a screw.

it looks like a wonderful machine!

it looks like a wonderful machine!