gattu marrudu

Member

Hi,

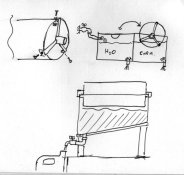

I am designing a system to develop very large format prints (about 1x2m).

I already have four 130x65cm trays in my darkroom and they take up the whole room. So I thought about a rotary system.

My idea is to use a sewage PET tube (they are very thick and solid and sell in many sizes) and a dual chamber tank.

The tube (~40cm ø) should be held by custom built stainless steel clamps, probably fixed to the tube by means of steel screws, and converging to a hub (sort of a bird's paw shape). The clamps are held by two metal tripods or similar and they can rotate by means of bearings.

The tank should have one partition where chemicals are poured and then dumped, and another with constantly running water. Each partition would be large enough to soak less than half of the tube in the chemical/water. It should be slightly larger than 1x2m. The bottom of the tank has a slope and a fairly large tap at the end so the chemicals can flow out easily. The tap in the water tank is left slightly open so the chmicals and byproducts, heavier than water, are flushed by the bottom. the whole tank is raised so a bottle/container can be put below it to collect the flushed chemicals.

If the tank has a metal frame it can have two pairs of U-shaped dents on the top edges, where the hub of the tube can sit, thus eliminating the need for tripods.

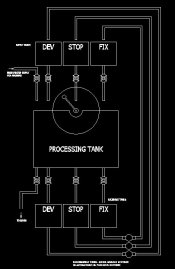

Processing:

- The drum is put in the empty half of the tank, while the other is filled with water.

- Developer is poured in and the drum is spun by means of a motor or (poor/lazy man's solution) a crank.

- Developer is dumped back to its container. Since this can take up a while, the drum is transferred to the water tank, which rinses the developer off the print in the meanwhile.

- The chemical tank is rinsed and flushed.

- This process is repeated for each step of stop, fix, hypo clearing etc. following the useful advice on LLoyd Erlick's single tray method: http://www.heylloyd.com/technicl/single.htm

- The print is taken out of the drum and dried.

Advantages of this method:

- You can achieve archival quality by using as many developing/fixing/clearing steps as you need, using the minimum space

- Print is rinsed after each step so the chemicals are not contaminated

- the drum does not touch the bottom of the tank, so the "dirty" water in the water tank is flushed by the bottom, and the print receives fresh water from the top.

Problems:

- A drum this size is very heavy and large. The main issue is to lift it over the tank edge and put it on the other tank, and then back for each step. To do this you either need an assistant, or a mechanical system to lift the drum. I have thought about two steel ropes and pulleys attached to the ceiling, but it seems too complicated

- Taking the wet print out of the drum. A solution coud be using a thick plastic sheet to hold the print, like in some Jobo drums. What is dreadful about this, though, is that if you are not careful enough, a hard edge of the plastic sheet can touch the wet print while you are taking it out, and scratch it.

- Will the back of the print be rinsed adequately? Ridges shoud be added to the above mentioned plastic sheet, or a separate tank can be built outside the darkroom just for the final rinse.

- One of the clamps should be screwed in before developing and taken off after rinsing. A simpler solution might be found.

I would appreciate some feedack, and hope this can insipre somebody else.

gm

I am designing a system to develop very large format prints (about 1x2m).

I already have four 130x65cm trays in my darkroom and they take up the whole room. So I thought about a rotary system.

My idea is to use a sewage PET tube (they are very thick and solid and sell in many sizes) and a dual chamber tank.

The tube (~40cm ø) should be held by custom built stainless steel clamps, probably fixed to the tube by means of steel screws, and converging to a hub (sort of a bird's paw shape). The clamps are held by two metal tripods or similar and they can rotate by means of bearings.

The tank should have one partition where chemicals are poured and then dumped, and another with constantly running water. Each partition would be large enough to soak less than half of the tube in the chemical/water. It should be slightly larger than 1x2m. The bottom of the tank has a slope and a fairly large tap at the end so the chemicals can flow out easily. The tap in the water tank is left slightly open so the chmicals and byproducts, heavier than water, are flushed by the bottom. the whole tank is raised so a bottle/container can be put below it to collect the flushed chemicals.

If the tank has a metal frame it can have two pairs of U-shaped dents on the top edges, where the hub of the tube can sit, thus eliminating the need for tripods.

Processing:

- The drum is put in the empty half of the tank, while the other is filled with water.

- Developer is poured in and the drum is spun by means of a motor or (poor/lazy man's solution) a crank.

- Developer is dumped back to its container. Since this can take up a while, the drum is transferred to the water tank, which rinses the developer off the print in the meanwhile.

- The chemical tank is rinsed and flushed.

- This process is repeated for each step of stop, fix, hypo clearing etc. following the useful advice on LLoyd Erlick's single tray method: http://www.heylloyd.com/technicl/single.htm

- The print is taken out of the drum and dried.

Advantages of this method:

- You can achieve archival quality by using as many developing/fixing/clearing steps as you need, using the minimum space

- Print is rinsed after each step so the chemicals are not contaminated

- the drum does not touch the bottom of the tank, so the "dirty" water in the water tank is flushed by the bottom, and the print receives fresh water from the top.

Problems:

- A drum this size is very heavy and large. The main issue is to lift it over the tank edge and put it on the other tank, and then back for each step. To do this you either need an assistant, or a mechanical system to lift the drum. I have thought about two steel ropes and pulleys attached to the ceiling, but it seems too complicated

- Taking the wet print out of the drum. A solution coud be using a thick plastic sheet to hold the print, like in some Jobo drums. What is dreadful about this, though, is that if you are not careful enough, a hard edge of the plastic sheet can touch the wet print while you are taking it out, and scratch it.

- Will the back of the print be rinsed adequately? Ridges shoud be added to the above mentioned plastic sheet, or a separate tank can be built outside the darkroom just for the final rinse.

- One of the clamps should be screwed in before developing and taken off after rinsing. A simpler solution might be found.

I would appreciate some feedack, and hope this can insipre somebody else.

gm