Cyanotype diapositives seem to be currently of interest: if a flexible substrate (plastic film) is acceptable, rather than a rigid one (glass), then I'd recommend trying the transparency films (e.g. from Pictorico or PermaJet) intended for making d*g*tal negatives - they take aqueous iron-based sensitizer solutions very well, and the zeolyte coating holds the image nanoparticles without 'bleeding'.

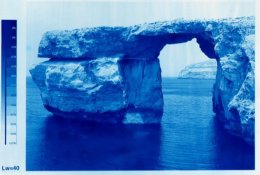

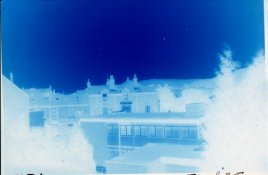

Six years ago, when I was testing cyanotype negative-making in camera, I also made one or two diapositive contact prints on Pictorico OHP transparency film coated with my New Cyanotype sensitizer. Tonalities were very good, the only problem was in laying down the coat evenly: my usual glass rod coater was impossible, suffering horrible friction on the ceramic-treated surface of the film. A squeegee or foam brush was better - but the example below still shows obvious imperfections. See attached scans, which were made in transmission mode.

I have long been meaning to try PTFE for a spreader rod ...

One thought about using plastic film as a substrate for alternative printing: it is presumably (I haven't tested) much more dimensionally stable than cellulose paper under wet processing - so might prove useful to those who favour multiple coating and developing for their image-making. If it works for new cyanotype, there is no reason why it should not also work for platinum, palladium and other siderotype processes. It also has the advantage that it can be used 'out of the box' with no pretreatment at all.

Mike

Six years ago, when I was testing cyanotype negative-making in camera, I also made one or two diapositive contact prints on Pictorico OHP transparency film coated with my New Cyanotype sensitizer. Tonalities were very good, the only problem was in laying down the coat evenly: my usual glass rod coater was impossible, suffering horrible friction on the ceramic-treated surface of the film. A squeegee or foam brush was better - but the example below still shows obvious imperfections. See attached scans, which were made in transmission mode.

I have long been meaning to try PTFE for a spreader rod ...

One thought about using plastic film as a substrate for alternative printing: it is presumably (I haven't tested) much more dimensionally stable than cellulose paper under wet processing - so might prove useful to those who favour multiple coating and developing for their image-making. If it works for new cyanotype, there is no reason why it should not also work for platinum, palladium and other siderotype processes. It also has the advantage that it can be used 'out of the box' with no pretreatment at all.

Mike