falotico

Member

- Joined

- Aug 31, 2012

- Messages

- 265

- Format

- 35mm

I visited the photographer Ctein last March at his home near San Francisco to buy some dye transfer prints. He had announced that he was closing down his dye transfer operations (although he still has laser and other color prints available) and I wanted to examine his portfolio to see which photographs I should buy. I'm glad I did because with dye transfer prints it is practically impossible to get an idea of what the actual print looks like from the image posted on his web site. There is no way to judge the richness and depth of color in a dye transfer except to see the object itself.

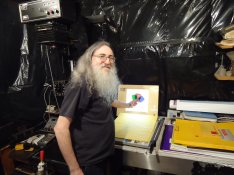

Ctein gave me permission to photograph him and to put these photos on the internet. I have posted more than twenty other photos from the session at my account--faloticoj--on flickr.com. The first image is of Ctein in his dark room holding three wratten filters to separate the primary colors of red, blue and green. Next to him is the enlarger which he used to expose the raw matrix material.

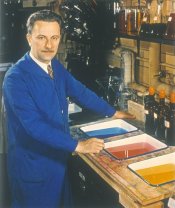

Ctein used the Eastman Kodak dye transfer process and materials. He has visited EK and discussed his methods with people there. The man who invented the Kodak dye transfer process, Louis Condax, is shown in a vintage photo next to the trays of dye solution. Ctein has contacted Condax's son and has studied notes and DT materials which belonged to Louis Condax. Ctein noted that both he and Condax did not mind if the tanning developer oxidized a bit before it was used to develop the matrix emulsions.

The next photos show Ctein laying the magenta matrix on a final print which already has a cyan image on it; then finally, removing the yellow matrix from the dye bath.

Ctein varied the method recommended by Kodak by increasing the exposure of the red light matrix by several minutes. Alas, such artistry will be lost since he has run out of Kodak materials and will no longer be making DT prints. He told me that he had contacted EK when they announced that they would discontinue producing DT materials. He asked them how many customers do you need to continue making these supplies? They told him, "You don't understand--you yourself already buy sixty per cent of what we produce." So there was no market for this process.

However a Mr. Brown(?) has manufactured matrix stock which should be a close substitute for the Kodak materials--it differs in that it is orthochromatic while the EK product was panchromatic. Ctein also says that the Kodak yellow dye is no longer available--yellow dye is a bugaboo in color photography. However another substitute should work. Dye transfer is still with us, but the magnificent Kodak version is gone with the wind. Ctein was a master of that process.

Ctein gave me permission to photograph him and to put these photos on the internet. I have posted more than twenty other photos from the session at my account--faloticoj--on flickr.com. The first image is of Ctein in his dark room holding three wratten filters to separate the primary colors of red, blue and green. Next to him is the enlarger which he used to expose the raw matrix material.

Ctein used the Eastman Kodak dye transfer process and materials. He has visited EK and discussed his methods with people there. The man who invented the Kodak dye transfer process, Louis Condax, is shown in a vintage photo next to the trays of dye solution. Ctein has contacted Condax's son and has studied notes and DT materials which belonged to Louis Condax. Ctein noted that both he and Condax did not mind if the tanning developer oxidized a bit before it was used to develop the matrix emulsions.

The next photos show Ctein laying the magenta matrix on a final print which already has a cyan image on it; then finally, removing the yellow matrix from the dye bath.

Ctein varied the method recommended by Kodak by increasing the exposure of the red light matrix by several minutes. Alas, such artistry will be lost since he has run out of Kodak materials and will no longer be making DT prints. He told me that he had contacted EK when they announced that they would discontinue producing DT materials. He asked them how many customers do you need to continue making these supplies? They told him, "You don't understand--you yourself already buy sixty per cent of what we produce." So there was no market for this process.

However a Mr. Brown(?) has manufactured matrix stock which should be a close substitute for the Kodak materials--it differs in that it is orthochromatic while the EK product was panchromatic. Ctein also says that the Kodak yellow dye is no longer available--yellow dye is a bugaboo in color photography. However another substitute should work. Dye transfer is still with us, but the magnificent Kodak version is gone with the wind. Ctein was a master of that process.

Attachments

Last edited by a moderator: