¡hola a todos!

Llevo un par de años siguiendo los hilos de este foro y estoy impresionado por el enorme conocimiento que tenéis muchos de vosotros.

Quiero compartir con ustedes un poco de mi investigación. Pido disculpas de antemano por mi inglés, no es mi lengua materna.

He visto algunos hilos aquí donde hablan de alternativas a los blanqueadores Rehalógenos, eso me llevó a investigar algunas patentes y encontré esa patente de Kodak que habla de un par de alternativas basadas en sales de sodio. US5464728A

La patente habla de dos blanqueantes con persulfato, uno que utiliza un acelerador como pre-baño y otro que utiliza un catalizador en la fórmula para obtener un blanqueo rápido y limpio. Esta última fue la fórmula que utilicé. Agregué los químicos en la siguiente secuencia:

Ácido dipicolínico 2,3gr

Nitrato férrico nonahidrato 2,52gr

Ácido acético 2,86ml

hidróxido de amonio 5ml

Persulfato de sodio 29,75gr

Cloruro de sodio 4,37gr

Agua para 500ml

Agregué el ácido dipicolínico, el nitrato férrico y el ácido acético, luego con hidróxido de amonio llevé el pH de la solución a pH 4 y finalmente agregué el persulfato y el cloruro de sodio. Verifique el pH nuevamente y ajústelo si es necesario para tener un pH final de 4.

El ácido dipicolínico junto con el nitrato férrico forman un catalizador que ayuda a acelerar el proceso de oxidación del persulfato. El agente halógeno a utilizar es cloruro, pero en la patente menciona que se puede sustituir por bromuro sin ningún problema, pero por cuestiones de economía se utiliza cloruro. .

Todos los productos químicos son fáciles de conseguir, excepto el ácido dipicolínico. Tuve que conseguir un proveedor que trabajara con Merck para poder comprarle a la marca. Sin embargo, parece que Santa Cruz Biotechnology tiene ácido dipicolínico a la venta en su sitio web, lo cual es conveniente si vives en Estados Unidos.

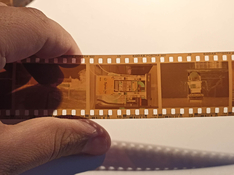

Probé el proceso Bleach con C41, E6 y ECN-2. Voy a añadir imágenes de muestra de la emulsión y una foto digitalizada, primero C41, luego E6 y al final ECN-2.

¿Qué problema puedo ver? La lejía se vuelve muy ácida con el paso de los días, lo que según la patente puede afectar el persulfato. ¿Cómo crear un buffet más estable, es posible? ¿Qué opinas del orden de la mezcla? ¿es correcto? Dejando de lado todo lo anterior, los resultados resultan ser muy buenos. Te explico el tiempo de cada proceso a continuación:

Proceso C41

Desarrollador 3:15 min.

Detener baño (ácido sulfúrico 1% + bisulfito sódico) 30 seg.

Blanqueador persulfato 3:00 min.

Primer Lavado 1:00 min.

Fijo (sodio) 4:00 min.

Segundo Lavado 2:00 min.

Ascenso final 1:15 min.

Proceso E6

Primer revelador 6:15 min.

Detener baño (ácido sulfúrico 1% + bisulfito sódico) 30 seg.

Lavar 30 seg.

Reexposición 1:00 min. Por lado.

Desarrollador de color 6:00 min.

Lavar 30 seg.

Pre-blanqueo 2:00 min.

Blanqueador persulfato 3:00 min.

Lavar 30 seg.

Fijar (sodio) 4 min.

Ascenso final 1:15 min.

Proceso ECN-2

Pre-baño (Remjet) 2:00 min.

Lavado para eliminar remjet: 3 a 4 cambios de agua hasta eliminar lo mejor posible el remjet.

Desarrollador 3:30 min

Detener el baño (ácido sulfúrico al 1%) 30 seg.

Lavar 1 min.

Retire la película del tanque y del carrete y retire cualquier resto de remjet. Lo volvemos a poner en el carrete.

Blanqueador persulfato (27°C) 3 min.

Lavar 1 min.

Fijar 4:00 min.

Lavar 2 min.

Ascenso final 1:15 min

No me extenderé más, espero vuestros comentarios. Muchas gracias por el tiempo de leerme.

{Moderator edit; translation added in English:}

Llevo un par de años siguiendo los hilos de este foro y estoy impresionado por el enorme conocimiento que tenéis muchos de vosotros.

Quiero compartir con ustedes un poco de mi investigación. Pido disculpas de antemano por mi inglés, no es mi lengua materna.

He visto algunos hilos aquí donde hablan de alternativas a los blanqueadores Rehalógenos, eso me llevó a investigar algunas patentes y encontré esa patente de Kodak que habla de un par de alternativas basadas en sales de sodio. US5464728A

La patente habla de dos blanqueantes con persulfato, uno que utiliza un acelerador como pre-baño y otro que utiliza un catalizador en la fórmula para obtener un blanqueo rápido y limpio. Esta última fue la fórmula que utilicé. Agregué los químicos en la siguiente secuencia:

Ácido dipicolínico 2,3gr

Nitrato férrico nonahidrato 2,52gr

Ácido acético 2,86ml

hidróxido de amonio 5ml

Persulfato de sodio 29,75gr

Cloruro de sodio 4,37gr

Agua para 500ml

Agregué el ácido dipicolínico, el nitrato férrico y el ácido acético, luego con hidróxido de amonio llevé el pH de la solución a pH 4 y finalmente agregué el persulfato y el cloruro de sodio. Verifique el pH nuevamente y ajústelo si es necesario para tener un pH final de 4.

El ácido dipicolínico junto con el nitrato férrico forman un catalizador que ayuda a acelerar el proceso de oxidación del persulfato. El agente halógeno a utilizar es cloruro, pero en la patente menciona que se puede sustituir por bromuro sin ningún problema, pero por cuestiones de economía se utiliza cloruro. .

Todos los productos químicos son fáciles de conseguir, excepto el ácido dipicolínico. Tuve que conseguir un proveedor que trabajara con Merck para poder comprarle a la marca. Sin embargo, parece que Santa Cruz Biotechnology tiene ácido dipicolínico a la venta en su sitio web, lo cual es conveniente si vives en Estados Unidos.

Probé el proceso Bleach con C41, E6 y ECN-2. Voy a añadir imágenes de muestra de la emulsión y una foto digitalizada, primero C41, luego E6 y al final ECN-2.

¿Qué problema puedo ver? La lejía se vuelve muy ácida con el paso de los días, lo que según la patente puede afectar el persulfato. ¿Cómo crear un buffet más estable, es posible? ¿Qué opinas del orden de la mezcla? ¿es correcto? Dejando de lado todo lo anterior, los resultados resultan ser muy buenos. Te explico el tiempo de cada proceso a continuación:

Proceso C41

Desarrollador 3:15 min.

Detener baño (ácido sulfúrico 1% + bisulfito sódico) 30 seg.

Blanqueador persulfato 3:00 min.

Primer Lavado 1:00 min.

Fijo (sodio) 4:00 min.

Segundo Lavado 2:00 min.

Ascenso final 1:15 min.

Proceso E6

Primer revelador 6:15 min.

Detener baño (ácido sulfúrico 1% + bisulfito sódico) 30 seg.

Lavar 30 seg.

Reexposición 1:00 min. Por lado.

Desarrollador de color 6:00 min.

Lavar 30 seg.

Pre-blanqueo 2:00 min.

Blanqueador persulfato 3:00 min.

Lavar 30 seg.

Fijar (sodio) 4 min.

Ascenso final 1:15 min.

Proceso ECN-2

Pre-baño (Remjet) 2:00 min.

Lavado para eliminar remjet: 3 a 4 cambios de agua hasta eliminar lo mejor posible el remjet.

Desarrollador 3:30 min

Detener el baño (ácido sulfúrico al 1%) 30 seg.

Lavar 1 min.

Retire la película del tanque y del carrete y retire cualquier resto de remjet. Lo volvemos a poner en el carrete.

Blanqueador persulfato (27°C) 3 min.

Lavar 1 min.

Fijar 4:00 min.

Lavar 2 min.

Ascenso final 1:15 min

No me extenderé más, espero vuestros comentarios. Muchas gracias por el tiempo de leerme.

{Moderator edit; translation added in English:}

hello everyone!

I have been following the threads on this forum for a couple of years and I am impressed by the enormous knowledge that many of you have.

I want to share with you a little of my research. I apologize in advance for my English, it is not my native language.

I've seen some threads here where they talk about alternatives to Rehalogen bleaches, that led me to research some patents and I found that Kodak patent that talks about a couple of alternatives based on sodium salts. US5464728A

The patent talks about two persulfate bleaches, one that uses an accelerator as a pre-bath and another that uses a catalyst in the formula to obtain fast and clean bleaching. The latter was the formula I used. I added the chemicals in the following sequence:

Dipicolinic acid 2.3gr

Ferric nitrate nonahydrate 2.52gr

Acetic acid 2.86ml

ammonium hydroxide 5ml

Sodium persulfate 29.75gr

Sodium chloride 4.37gr

Water for 500ml

I added the dipicolinic acid, ferric nitrate and acetic acid, then with ammonium hydroxide I brought the pH of the solution to pH 4 and finally added the persulfate and sodium chloride. Check the pH again and adjust if necessary to have a final pH of 4.

Dipicolinic acid together with ferric nitrate form a catalyst that helps accelerate the persulfate oxidation process. The halogen agent to be used is chloride, but the patent mentions that it can be replaced by bromide without any problem, but for reasons of economy chloride is used. .

All chemicals are easily available except dipicolinic acid. I had to get a supplier that worked with Merck to be able to buy from the brand. However, it appears that Santa Cruz Biotechnology has dipicolinic acid for sale on their website, which is convenient if you live in the United States.

I tested the Bleach process with C41, E6 and ECN-2. I am going to add sample images of the emulsion and a digitized photo, first C41, then E6 and at the end ECN-2.

What problem can I see? The bleach becomes very acidic over the days, which the patent says can affect the persulfate. How to create a more stable buffet, is it possible? What do you think of the order of the mix? it's right? Leaving aside all of the above, the results turn out to be very good. I explain the time of each process below:

Process C41

Developer 3:15 min.

Stop bath (1% sulfuric acid + sodium bisulfite) 30 sec.

Persulfate bleach 3:00 min.

First Wash 1:00 min.

Fixed (sodium) 4:00 min.

Second Wash 2:00 min.

Final ascent 1:15 min.

E6 process

First developer 6:15 min.

Stop bath (1% sulfuric acid + sodium bisulfite) 30 sec.

Wash 30 sec.

Reexposure 1:00 min. Per side.

Color Developer 6:00 min.

Wash 30 sec.

Pre-whitening 2:00 min.

Persulfate bleach 3:00 min.

Wash 30 sec.

Fix (sodium) 4 min.

Final ascent 1:15 min.

ECN-2 process

Pre-bath (Remjet) 2:00 min.

Wash to remove remjet: 3 to 4 changes of water until the remjet is removed as best as possible.

Developer 3:30 min

Stop bath (1% sulfuric acid) 30 sec.

Wash 1 min.

Remove the film from the tank and reel and remove any remaining remjet. We put it back on the reel.

Persulfate bleach (27°C) 3 min.

Wash 1 min.

Set 4:00 min.

Wash 2 min.

Final ascent 1:15 min

I will not expand further, I await your comments. Thank you very much for the time to read me.

Attachments

Last edited by a moderator: