holmburgers

Member

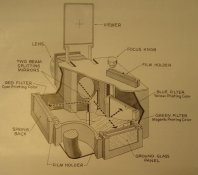

Lately I've been pipe dreaming about building a 3-color camera. This is not something I intend to do tomorrow exactly, but I still think there's some good that could come from talking about it and discussing the feasibility.

3-color cameras require a very precise optical path and placement of the reflectors/film-planes needs to be very exact. Since Computer Aided Design and Computer Numerical Control were in their infancy (if not still in the womb) when the last "one-shot camera" was made, it seems reasonable to assume that making one today might be much easier than it was then.

As I'm imagining it, the camera body could be assembled from a number of separate pieces, cut on some kind of CNC machine (?) and bolted together. The design would accomodate film holder placement; accurately spacing their distances.

The reflectors would then need to be mounted in frames that allow for fine adjustments and calibration after installation, with a provision to fit these frames in the aforementioned body.

The lens board & focusing standard would be fairly easy to make; requiring no great feat of precision. A well made bellows & focusing track would suffice. It'd be nice to connect this to a rangefinder as well.

Considering the need for low thermal expansion, excellent rigidity & an ability to be easily machined, what would be the best material? Steel, stainless steel, aluminum, brass, YbGaGe?

Knowing what kind of machines would be needed to do this work would help you choose a machine shop with the capability. Finding someone versed in CAD shouldn't be too difficult either. I've got at least 1 engineer friend I could bribe!

3-color cameras require a very precise optical path and placement of the reflectors/film-planes needs to be very exact. Since Computer Aided Design and Computer Numerical Control were in their infancy (if not still in the womb) when the last "one-shot camera" was made, it seems reasonable to assume that making one today might be much easier than it was then.

As I'm imagining it, the camera body could be assembled from a number of separate pieces, cut on some kind of CNC machine (?) and bolted together. The design would accomodate film holder placement; accurately spacing their distances.

The reflectors would then need to be mounted in frames that allow for fine adjustments and calibration after installation, with a provision to fit these frames in the aforementioned body.

The lens board & focusing standard would be fairly easy to make; requiring no great feat of precision. A well made bellows & focusing track would suffice. It'd be nice to connect this to a rangefinder as well.

Considering the need for low thermal expansion, excellent rigidity & an ability to be easily machined, what would be the best material? Steel, stainless steel, aluminum, brass, YbGaGe?

Knowing what kind of machines would be needed to do this work would help you choose a machine shop with the capability. Finding someone versed in CAD shouldn't be too difficult either. I've got at least 1 engineer friend I could bribe!