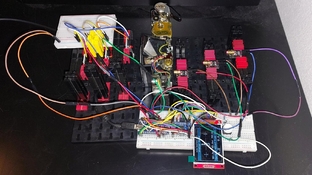

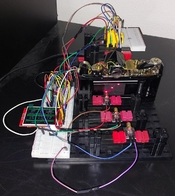

I have built Stuart Brown's shutter speed tester and I'd like to confirm that everything works beautifully. I have included some images where you can see the breadboard prototype mounted to some Fischer Technik (a very European construction toy). It looks like a rat's nest of wires and electronics - which it admittedly is - but it works very well and I have tested over 10 cameras already. I even wrote some custom firmware for it (currently sitting at my own Gitlab) to do some more extensive measurements and eventually statistics, but this is still a WIP. I also wrote a small calibration tool to verify the shutter times which also works really well with accurate readings up to 1/8000, so far!

As I am using a slightly different macro bellows to mount the thing in, I am currently making some 3D parts to print. I will update when the final product is done.

As I am using a slightly different macro bellows to mount the thing in, I am currently making some 3D parts to print. I will update when the final product is done.

)

) ).

).